Ball Mill

- Diameter

- 900mm~4500mm

- Capacity

- Up to 160tph

- Improvement

- The jack-up device adopts the hydraulic jack-up device independently. When the ball mill is in maintenance, only handling the hydraulic station can make the hydraulic jack go up and down. Compared to the common jack-up device, our jack-up device is characterized by simple, convenient and fast operation, with lower maintenance costs.

Description

- Introduction

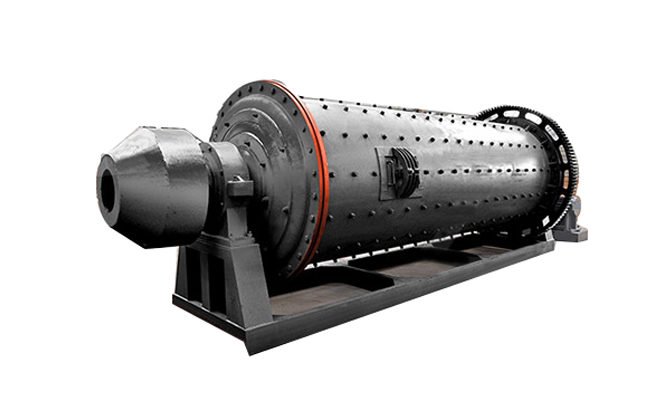

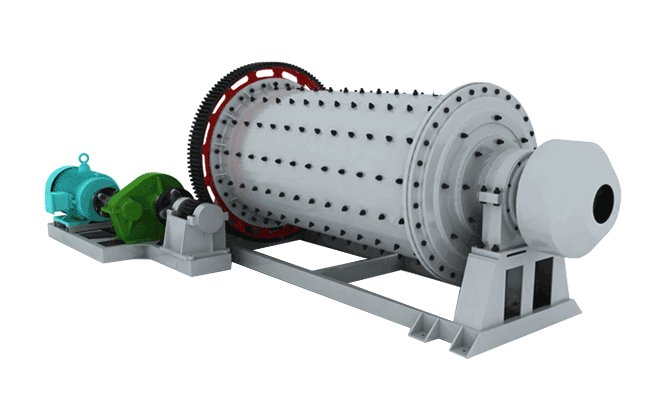

A traditional ball mill with discharging grid,Ball mill is the key equipment for smash the materials after they are primarily crushed.Ball mill is widely used for the dry type or wet type grinding of all kinds of ores and other grind able materials in cement, silicate product, new building material, refractory, fertilizer, black and non-ferrous metals and glass ceramic industry.

Advantages

-

1

Jack-up device, easy maintenancer; -

2

Hydrostatic and hydrodynamic bearings ensure smooth operation; -

3

Low-speed transmission is easy to start and maintain; -

4

The oil mist lubrication device ensures reliable bearing performance; -

5

The gas clutch adopts the flexible boot model; -

6

According to customer demand, the manganese steel liner and the wear resistant rubber liner can be customized for ball mills, with good wear resistance, long service life and easy maintenance.

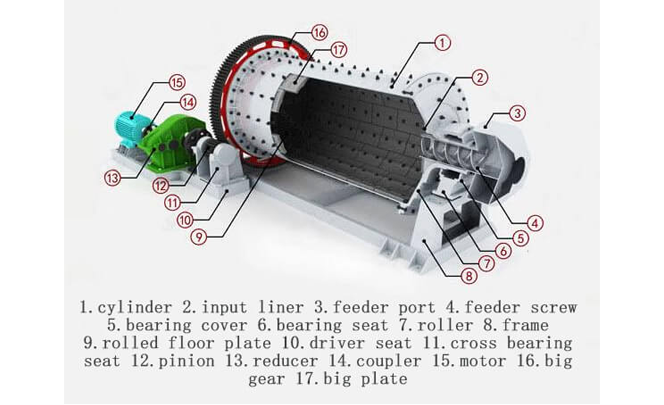

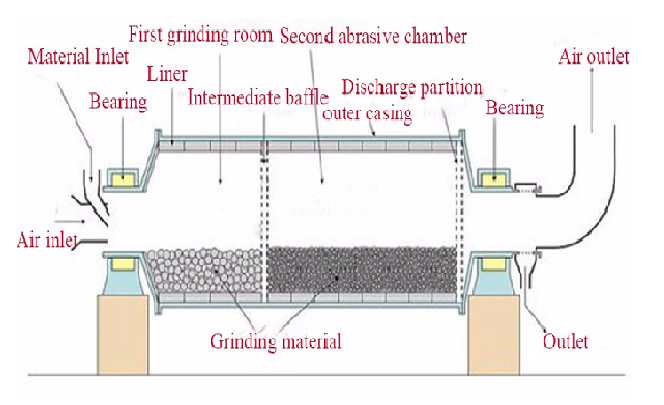

Structure

Ball Mill is a horizontal rotating device transmitted by the outer gear. The materials are transferred to the grinding chamber through the quill shaft uniformly. There are ladder liner and ripple liner and different specifications of steel balls in the chamber. The centrifugal force caused by rotation of barrel brings the steel balls to a certain height and impact and grind the materials. The ground materials are discharged through the discharging board thus the grinding process is finished. The main component is a cylinder with a reasonable diameter and length. Driven by the transmission device, the cylinder rotates with the materials fed from the cylinder entrance and crushed by the impacts of falling and autogenous grinding of the steel balls and ores in the cylinder. Due to the continuous material feed, the pressure pushes the materials to the outlet and the crushed materials are discharged from the cylinder outlet. Qualified materials flow from the cylinder outlet. In wet grinding, materials are removed by the flow of water.

Technical Parameters

| Model | Cylinder Diameter (mm) | Cylinder Length (mm) | Motor Model | Motor Power (kW) | Length (mm) | Width (mm) | Height (mm) | Capacity (t/h) | Effective Volume (m3) | Max. Ball Load (t) | Weight (kg) |

| MQSg 1212 | 1200 | 1200 | Y200L2-6 | 22 | 3512 | 2076 | 1620 | 0.17 ~4.1 | 1.14 | 2.4 | 9610 |

| MQSg 1224 | 1200 | 2400 | Y280M-8 | 45 | 5745 | 2352 | 1778 | 0.26~6.15 | 2.4 | 4.6 | 12692 |

| MQSg 1240 | 1200 | 4000 | JR117-8 | 80 | 7990 | 2210 | 2262 | 0.34~8.3 | 3.8 | 7.8 | 15932 |

| MQSg 1515 | 1500 | 1500 | Y280M-8 | 45 | 5740 | 3075 | 2280 | 1.4 ~4.5 | 2.2 | 5 | 17125 |

| MQSg 1530 | 1500 | 3000 | JR117-8 | 80 | 7253 | 3070 | 2280 | 2.8 ~9 | 5 | 10 | 21425 |

| MQSg 1536 | 1500 | 3600 | JR126-8 | 110 | 8595 | 3185 | 2280 | 3~11 | 5.4 | 11.4 | 24213 |

| MQSg 1545 | 1500 | 4500 | JR127-8 | 130 | 9680 | 3254 | 2370 | 3.5~12.5 | 7 | 12 | 27346 |

| MQSg 1830 | 1800 | 3000 | JR136-8 | 180 | 8250 | 3620 | 2785 | 4.5 ~27 | 6.65 | 14 | 31850 |

| MQSg 1836 | 1800 | 3600 | JR136-8 | 180 | 8866 | 3683 | 2785 | 4.5 ~29 | 8.2 | 13.8 | 35467 |

| MQSg 1845 | 1800 | 4520 | JR137-8 | 210 | 9808 | 3683 | 2785 | 5~35 | 10.2 | 19 | 38909 |

| MQSg 1856 | 1800 | 5620 | JR137-8 | 210 | 10909 | 3683 | 2785 | 6~40 | 12.2 | 22 | 41681 |

| MQSg 1870 | 1800 | 7020 | JR138-8 | 245 | 12404 | 3783 | 2735 | 7~50 | 15 | 31.5 | 45166 |

| MQSg 2122 | 2100 | 2200 | JR128-8 | 155 | 7135 | 4137.7 | 3083 | 5~29 | 6.6 | 20 | 38340 |

| MQSg 2130 | 2100 | 3000 | JR136-8 | 180 | 8220 | 4220 | 3083 | 6.5 ~36 | 9 | 27 | 43100 |

| MQSg 2136 | 2100 | 3600 | JR137-8 | 210 | 9154.5 | 4320 | 3433 | 7.5 ~42 | 10.8 | 23.5 | 45833 |

| MQSg 2140 | 2100 | 4000 | JR137-8 | 210 | 9654 | 4320 | 3083 | 7.5 ~45 | 12.8 | 22.5 | 47262.4 |

| MQSg 2145 | 2100 | 4500 | JR137-6 | 280 | 10350 | 4253 | 3125 | 10 ~50 | 13.5 | 23.6 | 52648 |

| MQSg 2230 | 2200 | 3000 | JR137-8 | 210 | 8220 | 3864 | 3183 | 7.5 ~45 | 9.8 | 20.6 | 44600 |

| MQSg 2430 | 2400 | 3000 | JR138-8 | 280 | 9023.5 | 4836.4 | 3490 | 7.2 ~92 | 11.5 | 22.5 | 59544.5 |

| MQSg 2436 | 2400 | 3600 | JR138-8 | 320 | 9604.5 | 4836.4 | 3490 | 8 ~100 | 13.8 | 25.5 | 63932.5 |

| MQSg 2442 | 2400 | 4200 | JR138-8 | 320 | 10204.5 | 4836.4 | 3490 | 8 ~110 | 16 | 30 | 67370 |

| MQSg 2721 | 2700 | 2100 | JR138-8 | 245 | 8300 | 4786.4 | 3495 | 7.2 ~84 | 10.7 | 23 | 66743 |

| MQSg 2727 | 2700 | 2700 | JR137-6 | 280 | 8901 | 4786.4 | 3490 | 7 ~110 | 13.8 | 29 | 71030 |

| MQSg 2730 | 2700 | 3000 | JR1410-8 | 320 | 9610 | 5000 | 3495 | 8 ~115 | 15.3 | 32 | 83909.2 |

| MQSg 2732 | 2700 | 3200 | JR1410-8 | 320 | 10724 | 5000 | 3620 | 8 ~120 | 15.7 | 32 | 88073 |

| MQSg 2736 | 2700 | 3600 | JR158-8 | 380 | 10409 | 5150 | 3620 | 12~145 | 17.7 | 37 | 95300 |

| MQSg 2740 | 2700 | 4000 | JR158-8 | 380 | 10609 | 5150 | 3620 | 12.5 ~152 | 19 | 42 | 98454 |

| MQSg 2745 | 2700 | 4500 | JR1510-8 | 450 | 11534 | 5200 | 3670 | 13~160 | 22 | 40 | 100016 |

| MQSg 2747 | 2700 | 4700 | JR1510-8 | 475 | 11779 | 5571 | 4175 | 13~170 | 23 | 45 | 101645 |

| MQSg 2760 | 2700 | 6000 | JR1512-8 | 630 | 13299 | 5540.6 | 5140 | 15~200 | 30 | 60 | 119546 |

| MQSg 2836 | 2800 | 3600 | JR1510-8 | 400 | 10964 | 5350 | 3670 | 13~160 | 19.7 | 41 | 106350 |

| MQSg 3231 | 3200 | 3100 | TDMK630-36 | 630 | 12750 | 6750 | 5150 | 14~180 | 22.5 | 45 | 115430 |

| MQSg 3245 | 3200 | 4500 | TDMK800-36 | 800 | 13896 | 7200 | 5152.5 | 95~110 | 32.8 | 65 | 147588 |

| MQSg 3645 | 3600 | 4500 | TDMK1250-40 | 1250 | 18280 | 7700 | 5496 | 115~170 | 41.5 | 76 | 195727 |

Send us a message

If you need our products please write down any questions, we will reply as soon as possible.