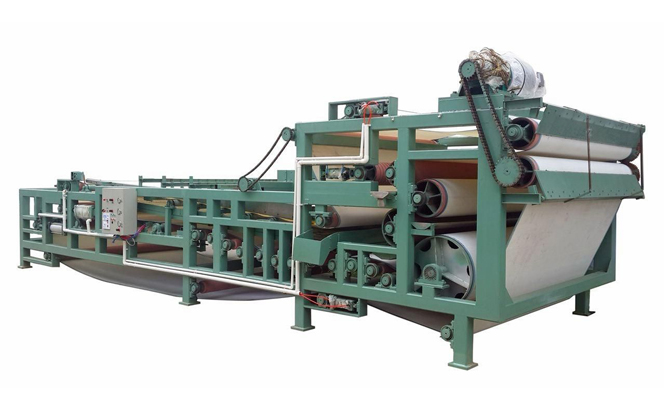

Belt Filter Press

- Introduction

- Sludge belt filter is pressing in original belt type filter based on increased concentration, sludge inspissation machines including condensed section, dehydration section, sludge mixed reaction system, which can be directly can put the second pond sludge (99.2-99.6%) moisture content of concentrated dehydration, eliminating the traditional enrichment pool, saving a lot of investment.

- Capacity

- 6-20t/h

Description

- This belt filter press is used for sewage treating. Because of pressing roller adopt different arrangement and combination can form a lot of different type. The structure is simple, dehydration high efficiency, large in capacity, less energy consumption, low noise, high degree of automation, can continuous operation and easy to maintenance etc, and its cost and operation cost than plate and frame filter press reduced by 30% or more, therefore become the first choice of urban sewage treatment equipment.

Advantages

-

1

Usually used for mining industy such as coalwashing metallurgy. -

2

Feeding, filtering and washing, deslagging, cloth filter regeneration it can continuously and automaticallycomplete, a high degree of automation. -

3

To material to multistage advection or backwashing, filtrate (mother liquor) and liquid detergent can separate set liquid. -

4

Modular design, flexible combination, strong adaptability. -

5

PLC control, facilitate remote and centralized control. -

6

The serpentine rectification, solve the filter cloth run partial and discount.

Structure

1.Preprocessing of flocculation. Mix polymer with the sludge to permits the agglomeration of particles.

2.Distribute the flocculated sludge onto the Gravity Dewatering Zone. The slurry moves through a series of plows and the free liquid is removed by gravity drainage porous.

3.Then the slurry moves into the Long Wedge Zone and became loosely structured cake.

4.The loosely structured cake proceeds forward and enter into the Roller Pressing Zone, which consists of a combination of rollers that decrease in size and accordingly can produce the medium and high pressure to squeeze.

5.Finally the cake is scraped off the belts and discharged. At the same time, both belts separate and back to the beginning of the process.

Technical Parameters

| Model | Filters width (mm) | Motor Power (kw) | Filters tension (KN/m) | Filterthe running speed of the tension (m/min) | Tensioner Adjustment Pressure (Mpa) | Tensioner adjustment pressure filters cleaning the pressure (Mpa) | Outline dimension L*W*H (mm) |

| DY1000 | 1000 | 1.1 | 0~8 | 1~9 | 0.2 | 0.3~0.5 | 5250*1950*2630 |

| DY1500 | 1500 | 1.5 | 0.3 | 5250*2450*2630 | |||

| DY2000 | 2000 | 2.2 | 0.4 | 5250*2950*2630 | |||

| DY2500 | 2500 | 2.2 | 0.5 | 5250*3450*2630 | |||

| DY3000 | 3000 | 3 | 0.6 | 5250*3950*2630 |

Send us a message

If you need our products please write down any questions, we will reply as soon as possible.