Chrome Ore Dressing Process

Chromium is an important alloy element for smelting stainless steel, internal heating steel, alloy tool steel, alloy structural steel and various types of cast iron. The chromite ore usually used to produce ferrochromium contains more than 38% chromium. For the beneficiation of chromium ore, the gravity separation process method is the first choice. Shakers, jiggers and spiral classifier are often used in production. Other chromium ore beneficiation includes magnetoelectric separation, flotation, chemical separation, etc.

Application

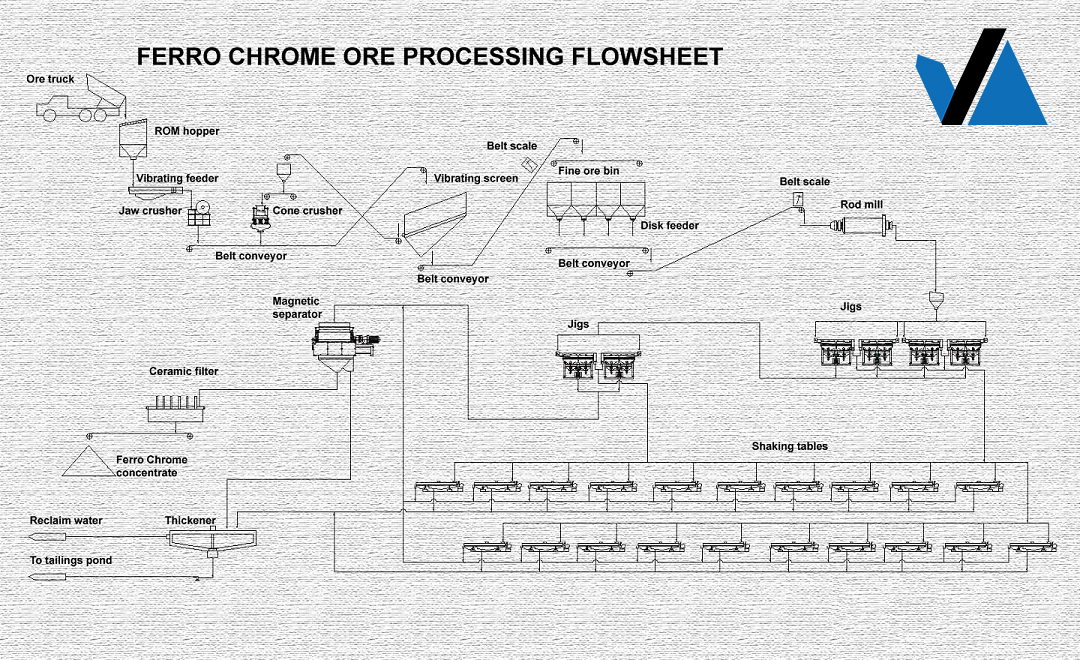

Chromium is one of the main alloying agents used in the steel industry, as an additive for the production of special steel such as stainless steel and heat-resistant steel. The Henan Victory ore gravity separation process is applied to a variety of chromium ores.The equipment of the chrome ore beneficiation production line includes jaw crusher, cone crusher, ball mill, spiral classifier, shaker, jigger and other equipment, in addition to feeders, conveyors, electronic control systems, etc.

The specific process is as follows:

The first is the crushing process, where the original large material needs to be broken into small materials. Large pieces of ore are first crushed by a jaw crusher, and then enters the cone crusher through the belt conveyor for secondary crushing. After that, the crushed material is screened out to the required size with a vibrating screen, the rest of the material is returned to the cone crusher and crushed again. All qualified materials will enter the next process.

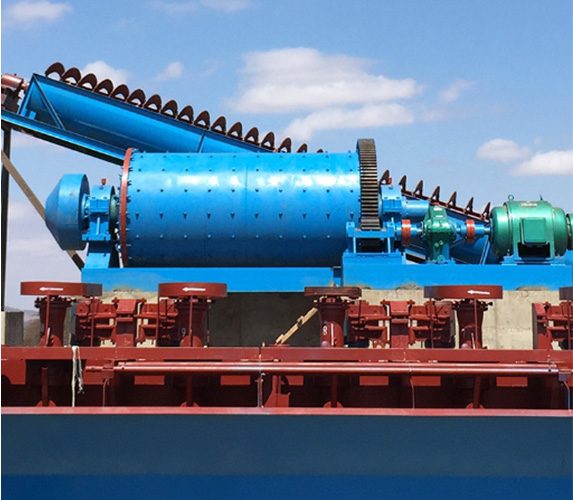

Next is the grinding process. The material crushed by the crusher enters the ball mill for crushing and grinding to a fine powder of about 0.2mm. The ground ore fines go to the next process.

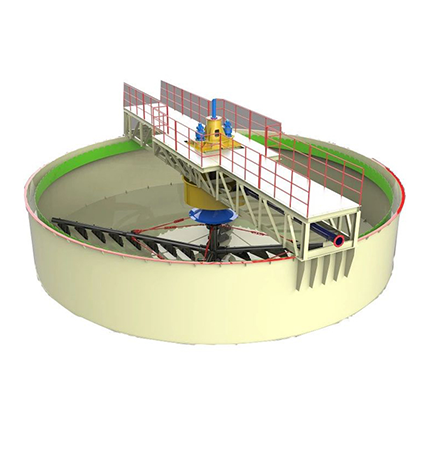

Finally is the most important gravity separation process. The ground fine mineral powder enters the jig for separation.After separation, the tailings enter the next stage of jigging machine for 4 times classification. All the tailings from the shaker is sent to the tailings bin after the waste is dry stacked.

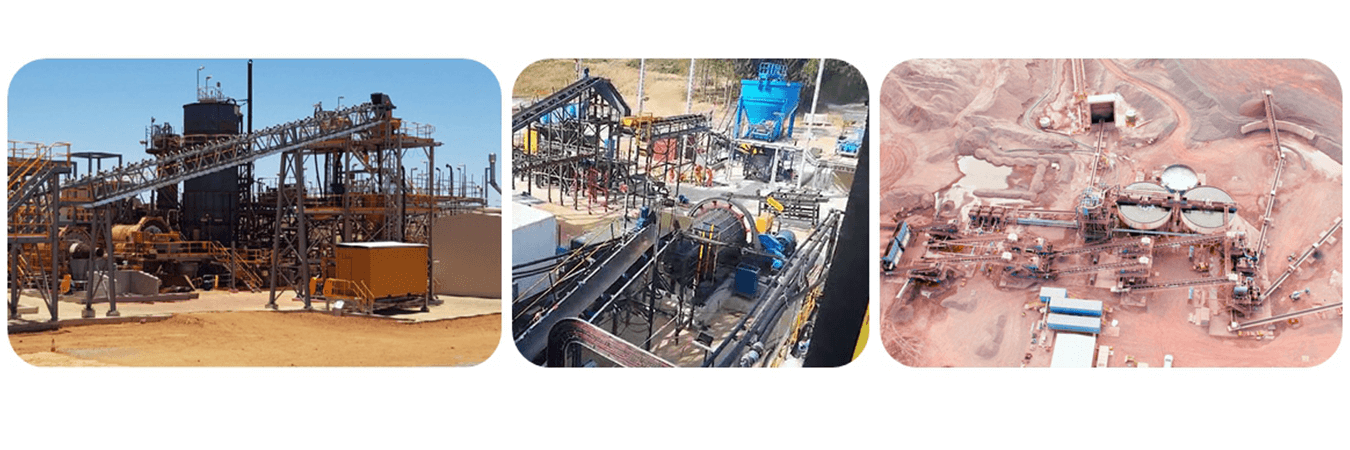

There are many cases of Henan Victory chromium ore dressing process. Welcome to visit our company!

A chrome ore factory in South Africa uses a traditional two-stage closed-circuit system for crushing. Jaw crushers and cone crushers are used to achieve two crushing of materials. In terms of crushing and classification, the use of ball mills with large processing capacity and small footprint can save More than 70% of energy. Use shaker and jig machine to improve the classification effect. Finally, dry tailings piles are used, which can obtain high-quality concentrates and is environmentally friendly to maximize customer profits.

If you need our products please write down any questions, we will reply as soon as possible.