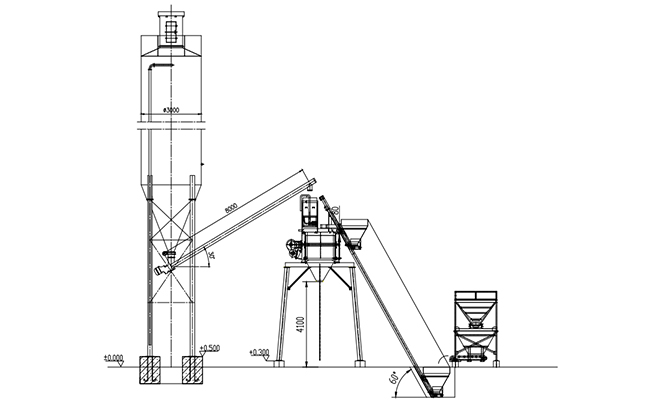

Concrete Batching Plant

- Capacity

- 25-180m3/h

- Improvement

- Stationary Concrete Batching Plants are very suitable for the project to make the concrete with a long period and amount of work, such as building construction, water conservancy engineering, bridge, and airport project, etc.

Description

- As per the aggregate transport system, there are two different type with the different capacity: Belt Conveyor Type or Skip Hopper Typer (Bucket Type ) . Skip Hopper Type: HZS-25, HZS-35, HZS-50 and HZS75 etc. Belt Conveyor Type : HZS-60, HZS-90, HZS-120 and HZS-180 Belt Conveyor Type Concrete Batching Plant is much more efficient than skip hopper type.

Advantages

-

1

Mixing Machine According to the different mixing effect, you can choose JS series twin shaft mixer, Sicoma concrete mixer, Planetary concrete mixer etc., usually we use JS series concrete mixer. -

2

Aggregate Batching Machine There are 3 types of batching machine to be chosen: Central Weighing Batching Machine; Belt Weighing Batching Machine; Separate Weighing Batching Machine. -

3

Control System There are two types control system you can choose: semi automatic and fully automatic. The only difference is whether it is with computer. Fully automatic can print some details, and visually display the working state of the stationary concrete batching plant and formula proportion. -

4

Cement Silo There are four types of powder storage system: Welded type cement silo, Bolted type cement silo, Low level horizontal cement silo and Mobile cement silo. Welded type is a complete unit with lower price; Bolted type will cost very little in shipment; Horizontal type is low-level; Mobile type is convenient to move around.

Working Principle

The aggregates will be loaded into the batching machine by wheel loader, then transported to mixing system after weighing. Meanwhile the water and additive are pumped into the weighing system by Water pump and Additive pump separately, then be transported into the mixing system.Cement and fly ash will enter their own weighing system through a screw conveyor, then enter the concrete mixer machine.

When the set mixing time is over, the finished products will be unloaded into the concrete mixer truck and transport the concrete to the worksite. If you need an on-site concrete batching plant, you may don’t need a concrete transit mixer.The above is the whole concrete production process and also the workflow of stationary concrete mixing plant. There are many details that need to be paid attention to. If you buy our machines, our staff will show you some routine repairs and maintenance.

Technical Parameters

| Items | HZS25 | HZS35 | HZS50 | HZS75 | HZS60 | HZS90 | HZS120 | HZS180 |

| Prpductivity | 25M3/H | 35M3/H | 50M3/H | 75M3/H | 60M3/H | 90M3/H | 120M3/H | 180M3/H |

| Main Mixer | JS500 | JS750 | JS1000 | JS1500 | JS1000 | JS1500 | JS2000 | JS3000 |

| Aggregate bin capacity | PLD1200 | PLD1200 | PLD1600 | PLD2400 | PLD1600 | PLD2400 | PLD3200 | PLD4800 |

| Loading Type | Skip Hopper | Belt Conveyor | ||||||

| Discharging Height | 3800/4200mm | |||||||

| Max Aggregate Size | 80/60mm | 80/60mm | 80/60mm | 80/60mm | 80/60mm | 80/60mm | 80/60mm | 80/60mm |

Send us a message

If you need our products please write down any questions, we will reply as soon as possible.