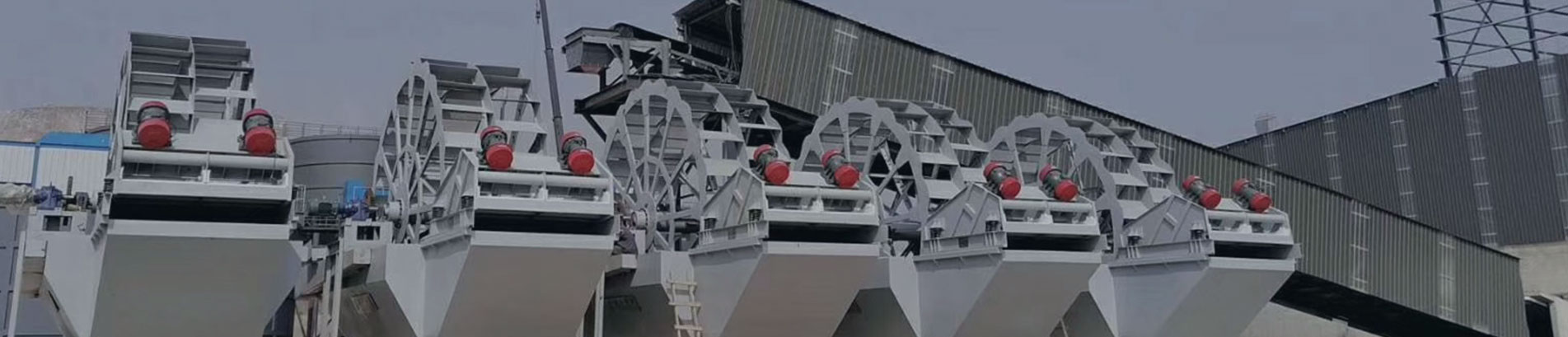

High Frequency Dewatering Screen

- Introduction

- Dewatering screen is mainly used for dewatering, desliming and demineralization. Therefore, it is also called sand dewatering screen, mining dewatering screen, slime dewatering screen, tailings dewatering screen, high frequency dewatering screen, etc.

- Capacity

- 10-200t/h

Description

- The high-frequency dewatering screen adopts the cylinder eccentric shaft vibrator and partial block to adjust the amplitude. The material screen has a long flowing line and many screening specifications. It has the characteristics of reliable structure, strong exciting force, high screening efficiency, small vibration noise, durability, convenient maintenance and safe use. Although they belong to the same dewatering equipment, the structure of the dewatering screen is different when it acts on different materials, such as the sand dewatering screen on the water washing sand production line and the tailings dewatering screen commonly used in the concentrator. The vibrating dewatering screen is mainly used in the wet sand production line, which can be used with the sand washing machine or alone.

Advantages

-

1

No rotating parts, no need to add lubricating oil. -

2

Simple structure, convenient maintenance, durable and low failure rate. -

3

Small driving power, no large starting current and low noise. -

4

When the screen body vibrates, there is relative vibration between the screen bars of the screen plate, and the gap between the screen plates is not easy to be blocked.

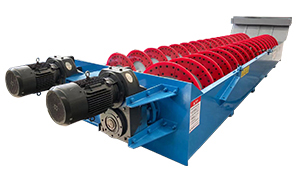

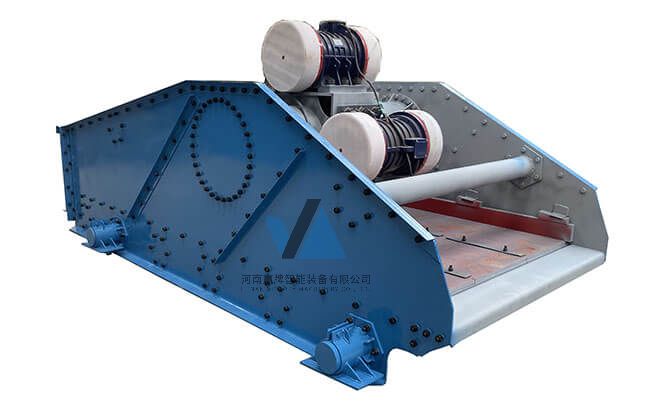

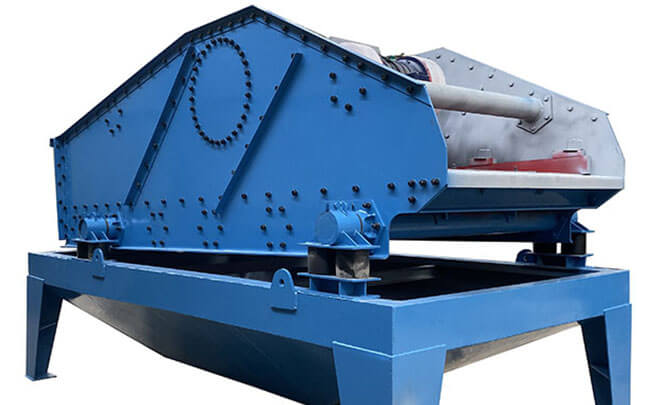

Structure

Dewatering screen is combined with advanced products - composite sieve plate and self vibration source group, coal industry is the ideal equipment for washing, desliming, dehydration, dewatering operation. High frequency dewatering screen structure: mainly composed of screen box, vibration exciter, suspension (or support) device and motor, etc. The motor drives the main shaft of the exciter to rotate through the V-belt, and the screen box vibrates due to the centrifugal inertia force of the unbalanced weight on the exciter. Different amplitudes can be obtained by changing the eccentric weight of the exciter.

Technical Parameters

| Model | TS1030 | 2TS1030 | 2TS1230 | 2TS1430 | TS1530 | TS1536 | TS1836 | TS2036 | |

| Production Capacity (t/h) | 10~30 | 10~30 | 40~60 | 60~80 | 80~100 | 80~100 | 100~150 | 130~180 | |

| Water content of upper sieve (%) | 24~27 | 22~26 | 22~26 | 22~26 | 22~26 | 22~26 | 23~28 | 23~28 | |

| Recycling Rate (%) | 70~85 | 75~90 | 75~90 | 75~90 | 75~90 | 70~85 | 70~85 | 70~85 | |

| Working Area (m2) | 2.8 | 2.8 | 3.4 | 4 | 4.3 | 5 | 6.1 | 6.8 | |

| Hole Size Of Screen (mm) | 0.25~ 0.35 | 0.1~ 0.35 | 0.1~ 0.35 | 0.1~ 0.35 | 0.1~ 0.35 | 0.25~ 0.35 | 0.25~ 0.35 | 0.25~ 0.35 | |

| layer of screen | 1 | 1 | 1 | 1 | 1 | 2 | 1 | 1 | |

| Motor | Model | Y112M-4 | Y112M-4 | Y132S-4 | Y132M-4 | Y132M-4 | Y132M-4 | Y132M-4 | Y160M-4 |

| Power (kw) | 2×1.1 | 2×1.1 | 2×2.2 | 2×3 | 2×3 | 2×3 | 2×3.7 | 2×7.5 | |

| Speed (rpm) | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | 1460 | 1460 | |

| Weight (T) | 0.6 | 0.6 | 1.28 | 1.4 | 1.55 | 1.75 | 2.9 | 5 | |

| Single fulcrum dynamic load (N) | ±290 | ±290 | ±400 | ±450 | ±450 | ±450 | ±720 | ±720 | |

Send us a message

If you need our products please write down any questions, we will reply as soon as possible.