Dissolved Air Flotation Machine

- Introduction

- Dissolved Air Flotation is an efficient flotation method for water clarification. The term refers to the method of producing flotation by dissolving air in the water under pressure and then releasing the pressure.

- Capacity

- 1-90 m3/h

Description

- The dissolved air flotation machine adopts a new and high-efficiency dissolved air equipment:micro-bubble generator, which replaces the traditional air-entraining equipment to dissolve air into the water, and installs a number of inclined pipe groups in the air flotation area, including a box, a slag scraper, The screw discharger together form a complete air floatation water purification device. The purpose of adding the inclined tube to the air flotation zone is to increase the air flotation area and greatly reduce the Reynolds coefficient, so that the air flotation can be avoided in the turbulent flow state, creating a good laminar flow state, and achieving the effect of shallow air flotation.

Advantages

-

1

Large processing capacity, high efficiency, and small area. -

2

The process and equipment structure are simple, easy to use and maintain. -

3

It can eliminate sludge expansion. -

4

Aeration into the water during air flotation has a significant effect on removing surfactants and odors in the water. At the same time, because aeration increases the dissolved oxygen in the water, it provides favorable conditions for subsequent treatment. -

5

For water sources with low temperature, low turbidity, and a lot of algae, the best effect can be achieved by using air flotation.

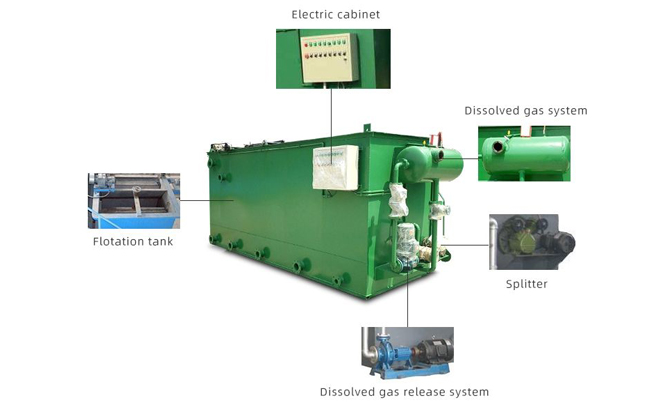

Structure

The main body of the advection type dissolved air flotation machine is composed of a dissolved air pump, a gas-water separator, a flocculation chamber, an air flotation contact chamber, a separation chamber, a slag collection tank, and a water collection tank.

Dissolved air flotation work process: First, pressurize the air to dissolve more air in the water, and then release a large number of micron-sized bubbles in the water through the pressure drop. During the floatation process of the small bubbles, it will absorb the suspended matter in the sewage Float together with the flocs, the dissolved air flotation machine uses this principle to achieve the effect of clean water quality.

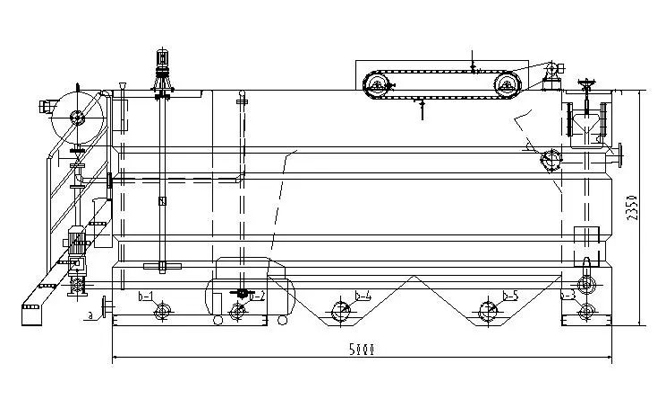

Technical Parameters

| Model | Treatment Capacity (m3/h) | Dissolved gas volume (m3/h) | Main Power (KW) | Scraper Power (KW) | Air Compressor Power (KW) | Air Compressor Model | Gas tank specification (mm) | Size(mm) |

| YW-5 | 1~5 | 1~2 | 3 | 0.37 | 1.5 | V-0.14-7 | 500*1000 | 3500*1700*2300 |

| YW-10 | 5~10 | 2~3 | 3 | 0.37 | 1.5 | V-0.14-7 | 500*1000 | 4500*1800*2300 |

| YW-20 | 10~20 | 5~7 | 5.5 | 0.37 | 1.5 | V-0.14-7 | 500*1000 | 6000*2500*2500 |

| YW-30 | 20~30 | 6~10 | 5.5 | 0.37 | 1.5 | V-0.14-7 | 500*1200 | 6800*2500*2500 |

| YW-40 | 30~40 | 8~13 | 5.5 | 0.37 | 1.5 | V-0.14-7 | 500*1500 | 7200*2500*2500 |

| YW-50 | 40~50 | 15~20 | 7.5 | 0.37 | 1.5 | V-0.14-7 | 500*1500 | 7500*2700*2500 |

| YW-60 | 50~60 | 18~27 | 7.5 | 0.37 | 1.5 | V-0.14-7 | 500*1800 | 8500*2700*2500 |

| YW-70 | 60~70 | 20~29 | 7.5 | 0.37 | 1.5 | V-0.14-7 | 600*1800 | 9000*2700*2500 |

| YW-80 | 70~80 | 24~32 | 11 | 0.37 | 1.5 | V-0.14-7 | 600*1800 | 9300*2800*2500 |

| YW-90 | 80~90 | 30~35 | 15 | 0.37 | 3 | V-0.36-7 | 600*2000 | 10000*3000*28000 |

Send us a message

If you need our products please write down any questions, we will reply as soon as possible.