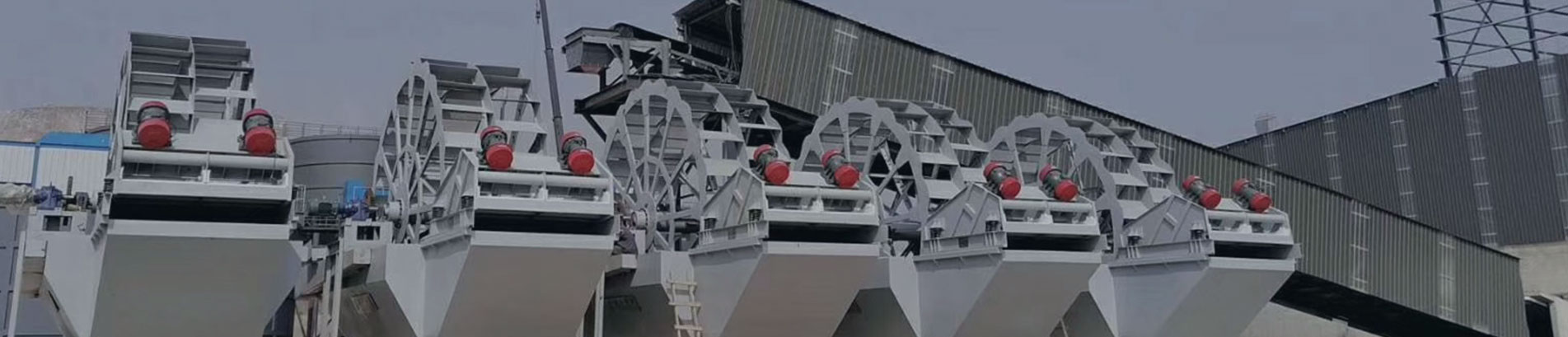

Drum Type Stone Washing Machine

- Capacity

- 30-250t/h

- Improvement

- The drum stone washing machine is widely used to clean the sediment before ore dressing of iron, manganese, limestone, tin ore and other ores with more mud. It can mix, wash, separate and desliminate the minerals and other hard to wash large ores. The ore washing efficiency can reach about 98%.

Description

- The drum washing machine is a large-scale equipment used in black and non-ferrous metallurgical mines, iron and steel, metallurgy, chemical industry and building materials to clean ore and stone. The larger processing capacity of the washing machine is an ideal equipment for enterprises that meet the requirements of large productivity for the cleanliness of ore and stone.

Advantages

-

1

The power of the rotary screen motor developed by our company is small, which is one-half to one-third of the other screen types. It can handle the same amount of materials and the operation time is only one-half of the other screen types, so the energy consumption is low. -

2

In the operation of the rotary screen, because of the small rotary speed and the sealed isolation cover, the noise can not be transmitted to the outside, so as to reduce the noise of the equipment. -

3

The upper cover of the equipment seal isolation can be disassembled, which will not affect the normal operation of the machine after disassembly, and make the maintenance very convenient.

Working

The drum stone washing machine is supported by four tugs, and the drum rotates at a low speed with the motor and reducer driving the big and small gears. The ore containing mud and stone powder is fed from the feed inlet through the feeding device, and the ore entering the rotating drum is cleaned. The drum is equipped with a mixing device with a specific angle, which is continuously taken, thrown and stirred. During the multiple circulation process from the feed end to the discharge end, the ore is continuously washed by the high-pressure water column in the direction of or in the direction of the reverse direction. The cleaned ore is discharged into the sewage tank at the discharge end. The dehydrated product is discharged and sent to the finished product pile. The sewage containing sludge flows out through the sewage device at the discharge end, and after the sedimentation in the three-stage sedimentation tank, it is ready for re washing and recycling.

Technical Parameters

| Feed particle size | Feed Size (mm) | Outlet size (mm) | Power (KW) | Speed (r/min) | Capacity (t/h) |

| Φ1.5×(11-15)m | 250 | 20-40 | 18.5 | 10.3 | 30-100 |

| Φ1.8×(11-15)m | 300 | 20-40 | 22 | 8.6 | 50-120 |

| Φ2×(13-20)m | 350 | 20-40 | 30 | 7.3 | 70-180 |

| Φ2.2×(13-20)m | 400 | 20-40 | 37 | 6.6 | 100-200 |

| Φ2.5×(13-20)m | 400 | 20-40 | 45 | 4.5 | 120-250 |

Send us a message

If you need our products please write down any questions, we will reply as soon as possible.