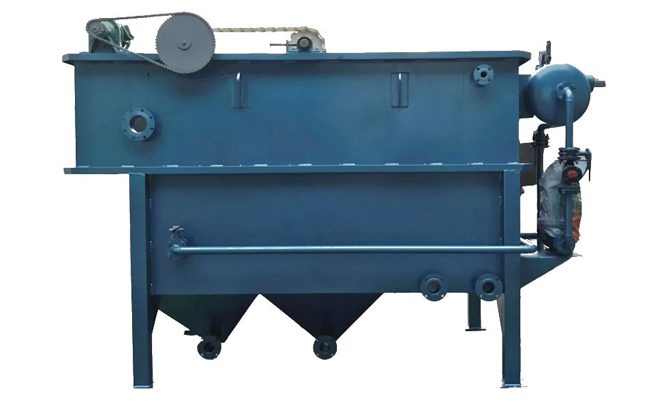

Electrolysis Air Flotation Machine

- Introduction

- Electrolysis air flotation process is a combination of electrolysis and air flotation. Compared with the chemical coagulation method of adding flocculant, this method can remove a wide range of pollutants, has a rapid response, a wide applicable pH range, and the sediment is dense and has a good clarification effect.

- Capacity

- 1-100 m³/h

Description

- The electrode plate of the electrolysis equipment can use different materials according to the different substances to be removed to produce strong flocculation, strong oxidation, strong reduction, strong air flotation, etc., in order to achieve the best treatment effect. Frequently used iron, aluminum, titanium, graphite, lead dioxide, etc. Each material has its suitable field of application. The design of electro-flocculation equipment and the selection of electrode plates are determined after a large number of research and development experiments and rich engineering practical experience.

Advantages

-

1

Low investment cost, low operating cost and Low maintenance and repair costs. -

2

No need to add any chemicals. -

3

Small footprint, simple operation and high degree of automation. -

4

Equipment processing time is short, processing efficiency is high. -

5

Adapt to a wide range of wastewater and can treat a variety of pollutants. -

6

The amount of sludge produced by equipment processing is small and the sludge density is high.

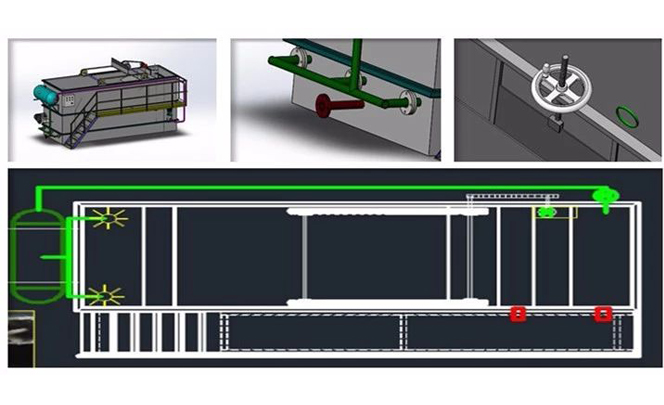

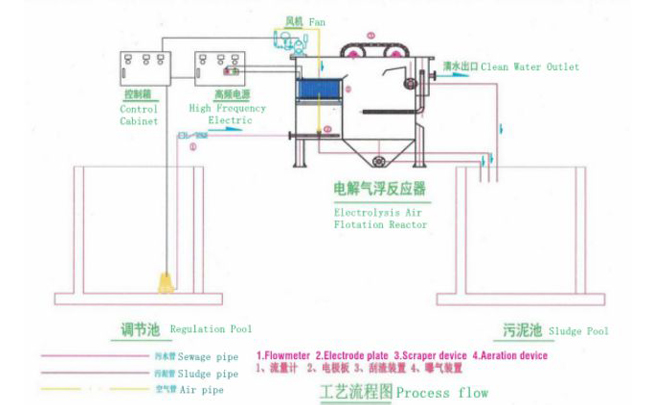

Structure

The air will be send by air compressor into air tank, then take in air dissolved tank by jet flow device, the air will be force to dissolve into water under 0.35Mpa pressure and forming dissolved air water, then send to air flotation tank.

Under the circumstance of sudden release, the air dissolved in water will be dissolve out and form vast microbubble group, which will be fully contact the flocculating suspended matter in sewage, the suspended matter was sent by pump and flocculation after adding medicine, the ascending microbubble group will adsorb in the flocculated suspended matter, made its density reduce and floated to water surface, thus reach the purpose of removing SS and CODcr etc.

Technical Parameters

| Model | Disposal capacity | Equipment size (m) | Dissolved air vessel size | Motor power | Equipment total weight | ||

| (m3/h) | Length | Width | Height | ((mm)) | (Kw) | (Kg) | |

| DJQF-1 | 1 | 1.0 | 0.8 | 1.0 | Φ200xh800 | 1.5 | 300 |

| DJQF-3 | 3 | 1.7 | 1.2 | 2.0 | Φ300xh1000 | 2.2 | 800 |

| DJQF-5 | 5 | 2.5 | 1.5 | 2.0 | Φ300xh1500 | 2.2 | 1200 |

| DJQF-10 | 10 | 4.6 | 1.7 | 2.0 | Φ400xh3000 | 4.0 | 2000 |

| DJQF-20 | 20 | 6.0 | 2.0 | 2.0 | Φ400xh3000 | 4.0 | 3200 |

| DJQF-30 | 30 | 7.2 | 2.0 | 2.1 | Φ500xh3000 | 5.5 | 4500 |

| DJQF-40 | 40 | 8.3 | 2.8 | 2.2 | Φ500xh3000 | 5.5 | 6000 |

| DJQF-50 | 50 | 9.3 | 3.2 | 2.2 | Φ600xh3000 | 7.5 | 7100 |

| DJQF-60 | 60 | 10.3 | 3.2 | 2.2 | Φ600xh3000 | 7.5 | 8500 |

| DJQF-80 | 80 | 11.2 | 3.5 | 2.5 | Φ800xh3000 | 11 | 9000 |

| DJQF-100 | 100 | 12.5 | 3.9 | 2.5 | Φ800xh3000 | 15 | 11000 |

Send us a message

If you need our products please write down any questions, we will reply as soon as possible.