Fluorite Ore Dressing Process

The main component of fluorite ore is calcium fluoride, which plays a very important role in metallurgy, chemical industry and other industries. The natural floatability of fluorite ore is good. For fluorite ore with different particle sizes, the flotation behavior is very different: coarse fluorite ore with larger particles has stronger selectivity during flotation, so the final concentrate has a higher taste, but the recovery rate is also relatively high. Low; for medium-sized fluorite ore, the final concentrate taste and recovery rate are relatively high; for fine-grained fluorite ore with small particle size, it is easier to lose, and its final concentrate taste and recovery rate are relatively high low.

Application

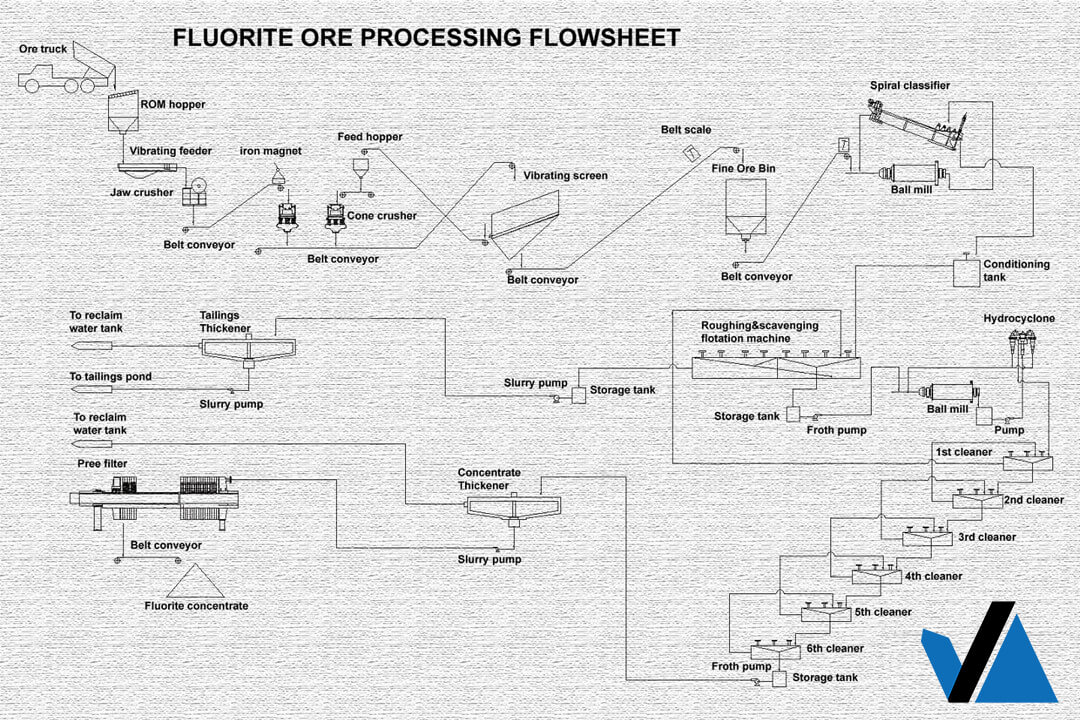

Fluorite beneficiation methods mainly include flotation and gravity separation. Flotation is mainly used to produce high-quality chemical grade fluorite powder, and gravity separation is mainly used to produce coarse metallurgical grade fluorite concentrate.The crystals of fluorite ore are brittle and fragile, so in the crushing process, pay attention to as little hammer crushing or impact crushing as possible. Most of them use simple and practical jaw crushers for coarse crushing, and the coarsely crushed materials enter the cylindrical screen. The cylindrical sieve screens out three kinds of materials of +30mm, 0-8mm, 8-30mm, and the materials of +30mm are entered into the hand-selecting belt conveyor for hand-selection. The hand-selected means that the fluorite and waste are manually observed. The difference between the stones and the process of sorting the fluorite nugget ore, due to the high labor intensity of the workers, the unstable sorting index and other factors, hand selection is basically seldom used, and most of the ore is directly crushed to the jig machine to effectively enter the selection level. Gravity separation and purification, 0-8mm and 8-30mm materials can be separated into trapezoidal jigs and large-particle jigs respectively, and the final concentrate and hand-dressed concentrate are mixed as metallurgical grade fluorite ore, and the tailings are dehydrated and deslimed Then enter the flotation process.

The flotation process is divided into grinding, grading, stirring, flotation and other processes. It is not much different from traditional flotation. However, due to the higher concentrate grade requirements, the flotation process is more frequent, generally 6 times The above selection, and the fluorite floatability is relatively good, usually only one scan is enough. The flotation of fluorite ore adopts heated flotation, and the main reagents used are shale oil, oxidized paraffin soap and so on. Fluorite is brittle and fragile, and it is easy to produce many high-grade powdery ore during crushing, and there will be a certain loss in the process of heavy and hand selection. Therefore, the heavy and hand-selected tailings of fluorite ore are often Carrying out flotation to improve the beneficiation index of the whole process, and at the same time maximize the economic benefit.

If you need our products please write down any questions, we will reply as soon as possible.