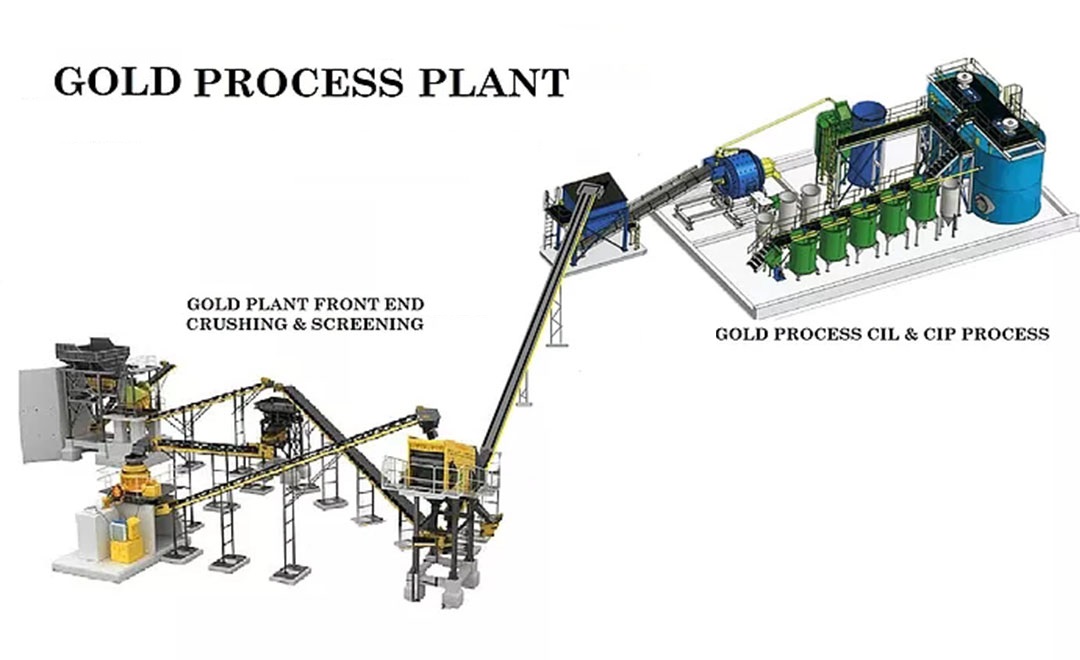

CIP Gold Carbon In Pulp Process

Gold extraction by carbon slurry process is mainly composed of cyanide leaching, activated carbon adsorption, desorption, and carbon regeneration. At present, it has become a major gold extraction method commonly used worldwide. It has the characteristics of fast adsorption rate, which can minimize the gold grade of the final tail liquid and reduce the loss of dissolved gold from the tail liquid.

Application

Gold extraction by carbon slurry is a common gold beneficiation process for effective recovery of gold-bearing minerals with a high degree of oxidation and low grade.Gold extraction by carbon slurry’s characteristic is that fresh (or regenerated) activated carbon is added to the last adsorption tank, and the direction of movement of the carbon is opposite to that of the slurry. Finally, the gold-loaded carbon is extracted from the first adsorption tank, so it is called countercurrent adsorption of carbon. From the front to the back of the carbon adsorption tank, the gold-containing grade of the solution gradually decreases, while the gold-loaded carbon that is picked up from the back tank gradually increases, and finally is raised by the first tank. Since the desorbed carbon or fresh carbon after acid washing and thermal regeneration in this countercurrent adsorption method of carbon has the strongest activity and the fastest adsorption rate, it can minimize the final gold grade of the final tail liquid and reduce the amount of dissolved gold from the tail. The chance of loss in the liquid, thereby increasing the adsorption rate. The specific process is as follows:

Raw material preparation

Grind the gold-containing materials to a particle size suitable for cyanidation, generally less than 28 mesh, and remove impurities such as wood chips. After concentration and dehydration, the concentration of the leaching slurry reaches 45%-50%.

Stirring leaching

Same as the conventional cyanidation method, generally 5-8 stirred tanks.

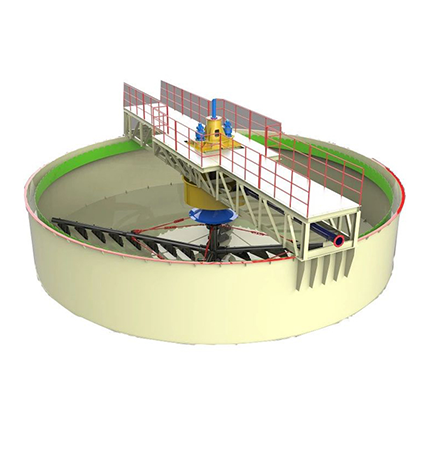

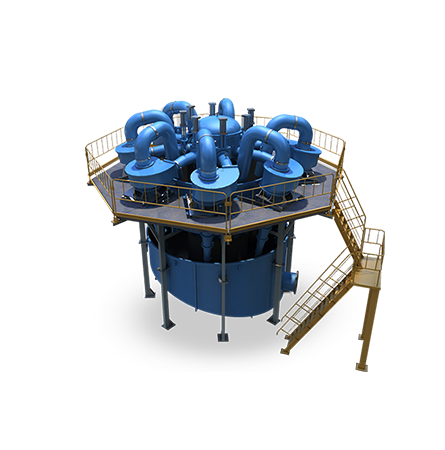

Carbon adsorption

The cyanide slurry enters the agitated adsorption tank (charcoal slurry tank). The Linghu Gold Mine in Henan Province is equipped with a grid screen and a slurry elevator in the slurry suction tank to realize the reverse flow of activated carbon and the slurry and absorb the dissolved gold in the slurry. Bridge screen can reduce the wear of activated carbon. At present, the sieve holes of the bridge screen are easily blocked by activated carbon and must be cleaned with compressed air.

Gold-loaded carbon desorption

This method greatly reduces the consumption of chemicals, the desorption rate is fast and the carbon cycle period is short. However, the process needs to cool before desorbing the expensive liquid to avoid boiling and splashing.

Regeneration of activated carbon

The activated carbon after desorption is first pickled with dilute sulfuric acid (nitric acid) to remove the carbonate and other accumulations. After being returned to use several times, it needs to be thermally activated to restore the adsorption activity of the carbon.

Gold extraction by carbon slurry method is mainly suitable for gold-bearing oxidized ores with high sludge content. Due to the high sludge content in the ore, solid-liquid separation is difficult. The existing filter cannot effectively separate the precious liquid and the slag, so the conventional cyanidation method cannot Obtain better technical and economic indicators. Practice shows that gold extraction by carbon slurry has achieved good results in industrial production.

If you need our products please write down any questions, we will reply as soon as possible.