CIL Gold Carbon Leaching Process

The carbon leaching method (CIL ) is developed on the basis of the gold extraction process for the replacement of fully viscous zinc cyanide powder. It is mainly suitable for processing low sulfur oxidized minerals with a lot of sludge. Electrolytic extraction by desorption, carbon pickling and thermal regeneration, chemical preparation, wastewater treatment and gold smelting and other processes. The coal leaching process is characterized by the fact that the leaching and adsorption operations are performed simultaneously, which saves the stirring tank and saves the investment. In recent years, newly built wet gold mining plants have generally adopted this process.

Application

The carbon leach process is suitable for treating low sulfur oxidized ores with a lot of slurry, and is not suitable for high silver gold ores. Usually, the gold / silver ratio can not exceed 1: 5. At present, the best conditions for using the carbon leach method are: PH = 10-11, sodium cyanide concentration not less than 0.015% , size Activated carbon particle 1-3.35mm, the carbon type is coconut shell activated carbon, and the leach pulp concentration is 40-45%.The main equipment of the carbon leaching plant includes crushers, belt conveyors, vibrating screens, ball mills, classifiers, dust removal, thickeners, slurry pumps, leaching tanks, adsorption tanks, carbon extraction equipment, carbon screens, safety screens, etc.

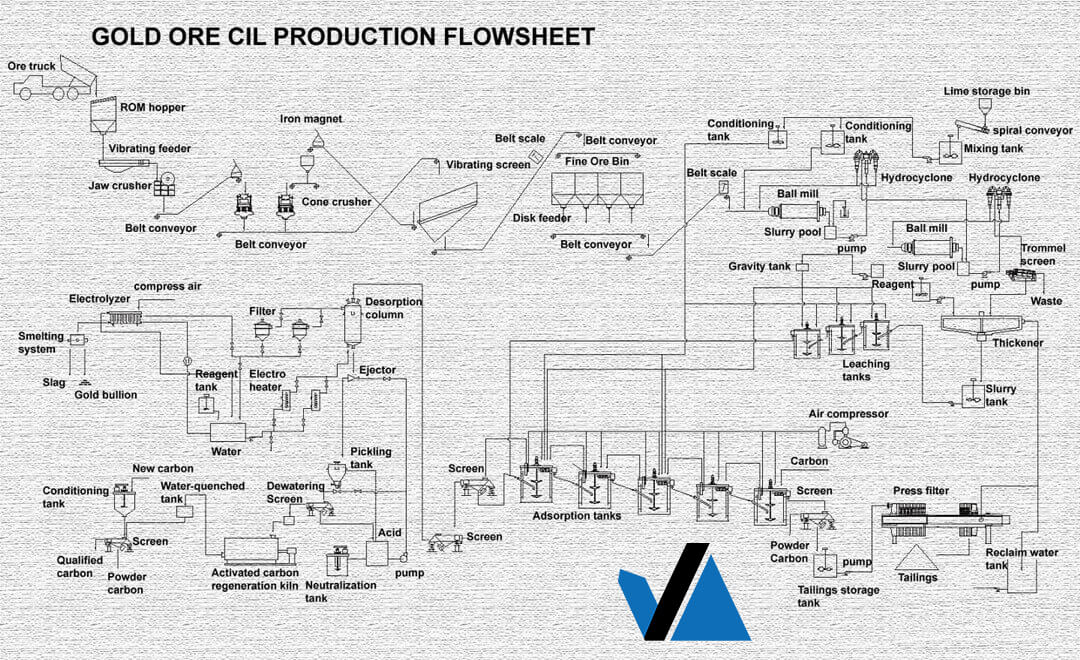

The specific process is as follows:

Leaching and adsorption

The carbon leaching method is characterized by the simultaneous leaching and adsorption of gold. The number of leaching stages is usually 6 to 10 stages. Since sodium cyanide has just been added to the first tank, the amount of gold leached out is low. Most carbon leach plants use the first tank as a prepreg tank. , The following tank is used as the leach adsorption tank. Each leach adsorption tank is equipped with a carbon screen to separate carbon and sludge. The suspension flows in the forward direction and the activated carbon flows in the opposite direction. That is, fresh activated carbon is added from the last leach adsorption tank, and the gold loaded carbon is leached from the first The adsorption tank is unloaded, after screening and washing, it is sent to operation desorption electro-extraction. The gold content of the suspension solution after adsorption by this method is generally 0.01 to 0.03 g / m³.

Cyanide leaching

In the leaching process, cyanide is used to leach gold and silver from the ore, forming a gold-silver cyanide complex. Lime is used to maintain a high pH to prevent the generation of toxic hydrogen cyanide gas. In a carbon leaching plant with a higher level of automation, a hydrogen cyanide gas detector is installed in the leaching and adsorption area.

The reaction of gold, silver, and cyanide requires oxygen. In theory, the oxygen consumption per gram of gold is 0.04 g, but in actual production the oxygen consumption is much higher. Because the mineral often contains various metal sulfides, it is also consumed. Oxygen reacts with cyanide. In actual production, 100 kpa medium pressure air is used to pass through the hollow shaft of the agitator. Airflow is generally controlled and measured with a rotameter.

Activated carbon adsorption

The commonly used activated carbon is coconut activated carbon, which has good adsorption performance and good wear resistance; Each adsorption tank should be equipped with a carbon screen, and the screen is usually 24 mesh 304 stainless steel. Carbon screens are mostly cylindrical and V-shaped, and our company uses vibrating screens.

Desorption

The desorption liquid in the high temperature and high pressure desorption method is aqueous solution of 0.1% sodium cyanide and 1% sodium hydroxide, the temperature is 150-170 ℃, the pressure is 0, 35 MPa and the desorption time is only 4-6 h to reach the process conditions. This method greatly reduces the consumption of chemicals, the desorption rate is fast and the carbon cycle period is short. However, the process needs to cool before desorbing the expensive liquid to avoid boiling and splashing.

The CIL process can shorten the leaching time, increase the leaching rate of gold and silver, reduce cyanide consumption, and can effectively leach the minerals containing more oxygen-consuming minerals.

There are many cases of Henan Victory gold carbon leaching process. Welcome to visit our company!

If you need our products please write down any questions, we will reply as soon as possible.