Graphite Ore Dressing Process

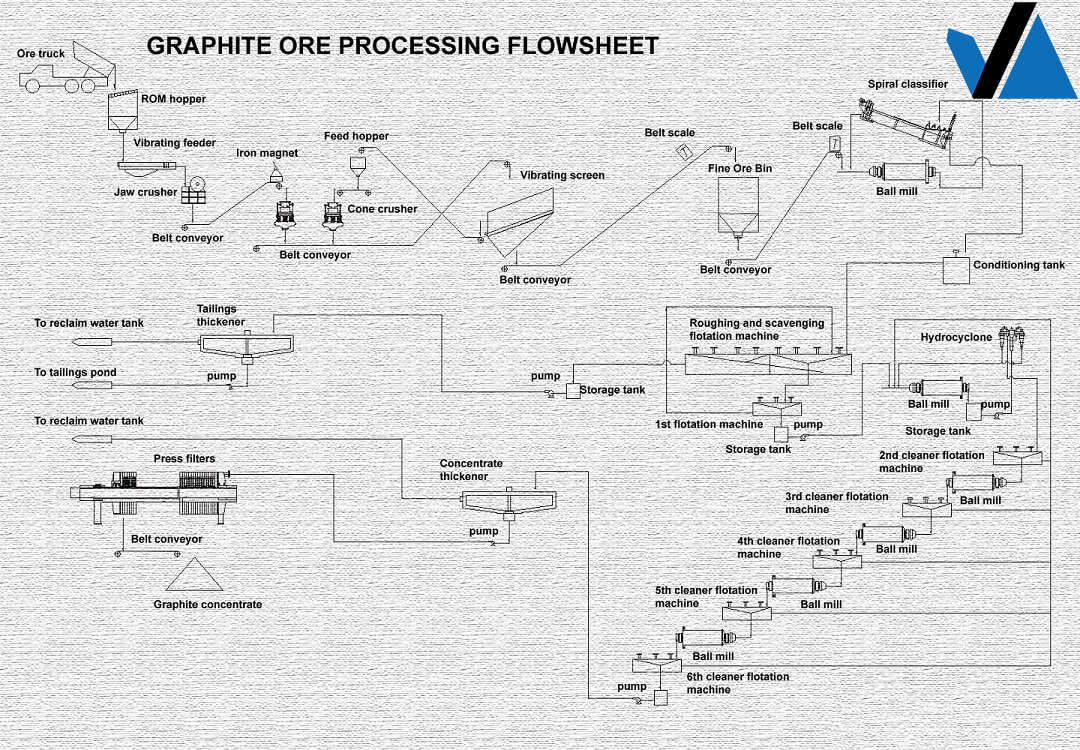

Graphite products are divided into two categories: flake graphite and microcrystalline graphite. Flake graphite has good natural flotability and basically uses flotation methods for beneficiation. The process usually includes three stages of crushing, grinding, and flotation.The microcrystalline graphite crystals are extremely small, and the particles are often embedded in the clay. It is difficult to separate. Usually, the mined graphite ore is simply hand-selected and then directly crushed into products for sale.Commonly used equipment for graphite beneficiation includes jaw crusher, cone crusher, ball mill, flotation machine, dehydration equipment, etc.

Application

Graphite ore can be used to manufacture wear-resistant materials, carbon products, lubricants for airplanes or trains, preservatives, polishers, etc.Graphite ore can be divided into crystalline graphite, flake graphite and graphite ore accompanied by a variety of gangues. The graphite ore dressing process adopts two combined beneficiation processes of multi-stage grinding, multi-stage flotation and gravity flotation.Crystalline graphite dressing process

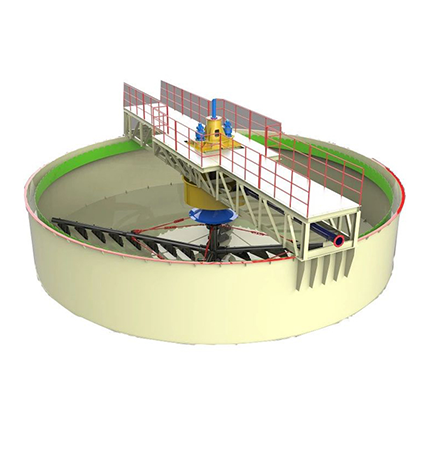

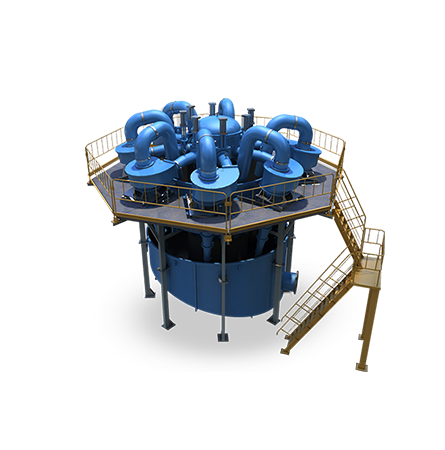

As the hardness of graphite ore is generally medium-hard or medium-hard to soft, the grade is generally between 2% and 10%, the crushing process is relatively simple, and three-stage open circuit, two-stage open circuit or one-stage crushing process are often used. Large pieces of graphite ore are evenly sent to the jaw crusher for coarse crushing by a vibrating feeder; then they enter the cone crusher for secondary crushing, and then graphite ore particles enter the circular vibrating screen for screening , The materials that meet the requirements enter the silo to be ground, and the materials that do not meet the requirements enter the cone crusher again to continue crushing. The crushed qualified graphite mineral material enters the ball mill for grinding processing, and then enters the spiral classifier for reasonable classification processing. The qualified materials enter the next step, and the unqualified materials need to be reground. Small and medium-sized mines that mainly process weathered ore are directly sent to the ball mill without crushing. The grinded graphite ore powder is completely mixed with the corresponding agent in the mixing tank and then enters the flotation machine to flotate the concentrate, and then enters the dryer to be dried to obtain the dried concentrate powder. Under normal circumstances, the concentrate The operating recovery rate can reach about 80%.

Cryptocrystalline graphite dressing process

Cryptocrystalline graphite has very small crystals, so it is also called microcrystalline graphite. Graphite particles are often embedded in clay. Cryptocrystalline graphite ore is of high grade, but it is difficult to sort. Usually, the mined graphite ore is directly crushed into products after simple hand selection,there is often no sorting operation for high-grade graphite. The general process is: raw ore → coarse crushing → medium crushing → drying → grinding → grading → packaging.

Characteristics of graphite ore dressing production line:

1. High-end equipment configuration, compact and reasonable layout, small total area, saving civil construction investment.

2. The degree of automation is relatively high, and the computer can be remotely controlled, and the investment cost of manpower and material resources is low.

3. More safe and stable operation, low failure rate, can save a lot of maintenance costs, no dust and noise, and will not cause damage to the environment.

4. The grade of the obtained concentrate has been increased by 10%, which has greatly improved the industrial value of graphite mineral materials, and the comprehensive recycling rate has been significantly improved.

If you need our products please write down any questions, we will reply as soon as possible.