Hammer Crusher

- Capacity

- 5~75t/h

- Improvement

- High-speed hammer impacts materials to crush materials. There are two ways of crushing (Wet and dry)

Description

- By adopting the developed technology and unique structural design, finished products processed by impact crusher boasts cubic shape without tension and cracks. It can crush stone smaller than 500mm with the compression strength lower than 350MPa, such as granite, limestone, concrete, etc

Advantages

-

1

Large crushing ratio, uniform discharge good granularity shape. -

2

Simple structure; -

3

Little wear and long life; -

4

High production efficiency; -

5

Suitable hammer crusher price; -

6

Variable hammer crusher specification.

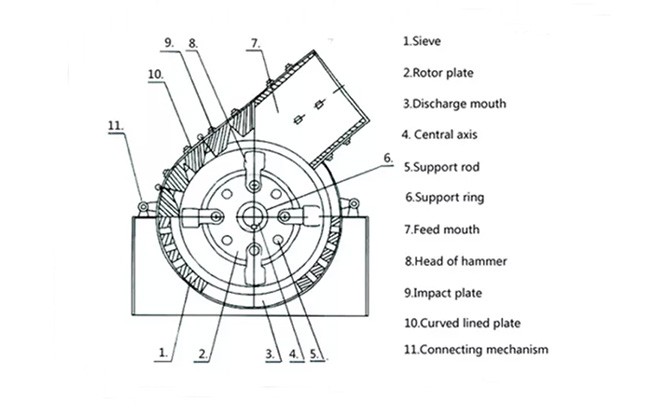

Working

The main parts of efficient compound crusher is rollers with hammer, the rollers consists of main shaft, sphere plate, axis roll and hammer. Motor drives roller in high speed running inner the crushing champ, the materials is send from top into the crusher, by the striking, impacting, shearing and grinding into power. At the roller bottom is a screen plate, it is used to collecting the materials whose size bellow the size of the screen plate, those size is bigger than the screen gap will be regrind by the hammer, finally discharged from the discharging opening.

Technical Parameters

| Model | Rotation Diameter (mm) | Discharge Size (mm) | Max. Feed Size (mm) | Capacity (t/h) | Power (kW) |

| PC-φ600X400 | φ600 | 10 〜30 | 100 | 12 〜15 | 18.5 |

| PC-φ600X600 | φ600 | 10 〜30 | 100 | 12 〜18 | 30 |

| PC-φ800X700 | φ800 | 10 〜45 | 200 | 13 〜35 | 37 |

| PC-φ800X800 | φ800 | 10 〜45 | 200 | 13 〜40 | 37 |

| PC-φ1000X1000 | φ1000 | 8〜60 | 300 | 30 〜80 | 55 |

| PC-φ1000X1300 | φ1000 | 8〜60 | 200 | 35〜100 | 110 |

| PC-φ1000X1500 | φ1000 | 8〜60 | 300 | 40〜100 | 132 |

| PC-φ1200X1600 | φ1200 | 10 〜70 | 500 | 100〜250 |

Send us a message

If you need our products please write down any questions, we will reply as soon as possible.