Description

- Introduction

- YGM series grinding mill is the new type mining equipment for making micro powders, fine powder, which is widely applied in the industries of metallurgy, mining, chemistry, cement, construction, refractory materials, ceramics industrial, pharmaceuticals and other industries.

Advantages

-

1

The grinding mill of YGM series is high efficient (twice as much as jet mill, mixing grinder and ball mill); -

2

The spare parts of grinding mills can serve much longer time (2-3 times longer than that of impact mill or turbo mill); -

3

High safety and reliability of the ultra fine mill (no rolling bearings and screws in the grinding cavity, so no problems caused by the wear of bearings or screws); -

4

The YGM Grinding mills are characterized by high fineness (final size: 325-3000 mesh, D97<5 micron).

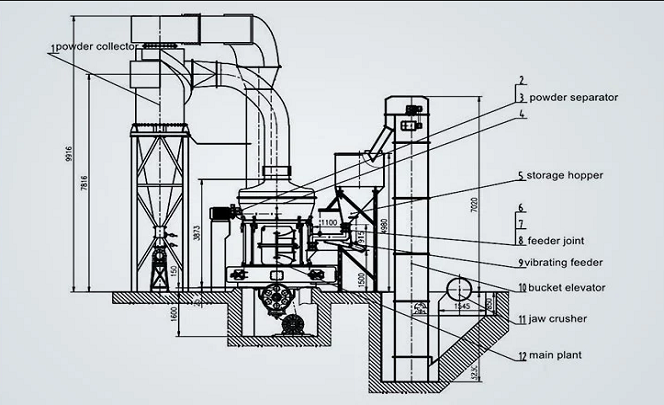

Structure

High Pressure Mill's complete structure is composed of main engine, analyzer (pulverizer), pipeline device, blower, finished cyclone separator, jaw crusher, bucket elevator, electromagnetic vibrating feeder, electronically controlled motor and other components.

High Pressure Mill's main machine consists of a frame, air inlet volute, blade,grinding roller, agrinding ring, cover and motor.

Technical Parameters

| Model | Piece of roller | Size of the roller (mm) | Size of the ring (mm) | Feed size(mm) | Fineness of powder (mm) | Capacity (t/h) | Motor power (kW) | Weight (without motor)(t) |

| YGM85 | 3 | 270×150 | 830×150 | ≤20 | 0.033-0.613 | 1.2-4 | 22 | 8 |

| YGM90 | 3 | 300×160 | 910×160 | ≤25 | 0.033-0.613 | 2.1-5.6 | 30 | 11 |

| YGM95 | 4 | 310×170 | 950×170 | ≤25 | 0.033-0.613 | 2.1-5.6 | 37 | 14 |

| YGM130 | 5 | 410×210 | 1280×210 | ≤30 | 0.033-0.613 | 2.5-9.5 | 75 | 24 |

Send us a message

If you need our products please write down any questions, we will reply as soon as possible.