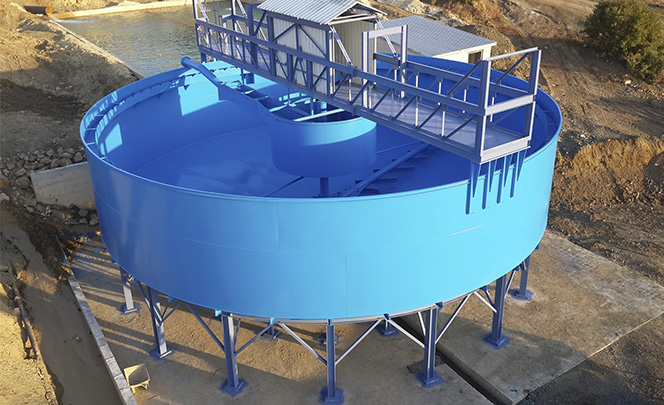

High Efficiency Thickener

- Introduction

- High efficiency thickener is circular, suspended solids settle down into bottom conical sludge tank by gravity, clear water flow away from overflow port around the upper tank, which is also called paste thickener. The port of the overflow is equipped with filter and baffle, which improve the water quality that poured out.

- Capacity

- 5-1400 t/d

Description

- High efficiency thickener promoted the structure of internal feed tube on the basis of traditional vertical flow sedimentation tank,optimized flocculation and deep solids compression provide paste consistency underflow and higher process rates, which greatly increase settling efficiency.

Advantages

-

1

High efficiency thickener automatic cleaning, automatic discharge slurry, solve manual operation. -

2

Following the principle of suspension filtration, media adsorption and settling, maximum purification. -

3

High efficiency thickener paste thickener use qualified carbon steel (or stainless steel), the machine has good strength and corrosion resistance. -

4

Low flocculant using cost, big capacity, high efficiency, stable performance. -

5

Small volume, small floor space, easy installation. -

6

Service life is about 15 years, low investment but remarkable economic benefit.

Working

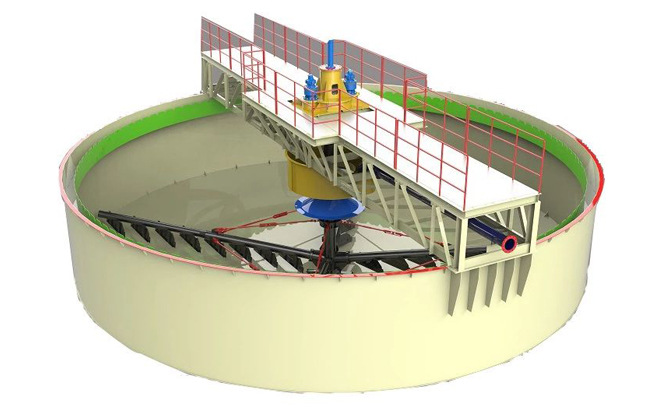

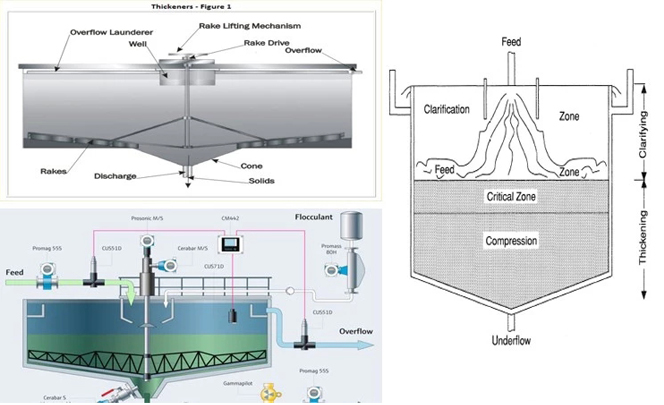

This thickener consists of round thickener and harrow scraping machine, the solid particles suspend in thickener settling by gravity, the pulp in the upper turn into clean water, so that the separation can be realized. Slime that sediment in the bottom of the thickener is discharged by the harrow scrapping continuously, and clean overflow from the upside.

Equipped with deaerating tank to prevent solid particles from adhering to the bubbles, and to subside like "parachute '. The feed tube is located below the liquid surface to avoid air blending with the pulp, and jagged overflow weir reducing the chance of uneven suction phenomenon.

Technical Parameters

| Model | Diameter (mm) | Depth (mm) | Sedimental area (m2) | Capacity (t/d) | Motor power (kw) |

| MT-2.5 | 2500 | 1850 | 4.9 | 5-22.4 | 1.5 |

| MT-3 | 3600 | 1800 | 10.2 | 5-28.5 | 1.5 |

| MT-5 | 5000 | 2956 | 16 | 16-90 | 4 |

| MT-6 | 6000 | 2956 | 28.3 | 98 | 4 |

| MT-7 | 7000 | 3000 | 38.5 | 140 | 4 |

| MT-8 | 8000 | 3318 | 50.2 | 185 | 5.5 |

| MT-9 | 9000 | 3376 | 63 | 210 | 5.5 |

| MT-12 | 12000 | 3600 | 113 | 370 | 5.5 |

| MT-15 | 15000 | 4000 | 176 | 580 | 5.5 |

| MT-18 | 18000 | 4400 | 255 | 960 | 7.5 |

| MT-20 | 20000 | 4400 | 315 | 1400 | 11 |

Send us a message

If you need our products please write down any questions, we will reply as soon as possible.