Hydraulic Cone Crusher

- Capacity

- 5~750t/h

- Improvement

- The Hydraulic Cone Crusher is the most ideal equipment for large stone crushing factory and mining industry.

Description

- Hydraulic cone crusher adopts computer optimization design to speed up main shaft speed. The unique crushing chamber replace system can quickly replace components in crushing chamber to meet different size requirement. It is widely used in the fields of metallurgy, construction, hydroelectric project, transport and chemical industries for crushing all sorts of hard and above medium hard ores and rocks.

Advantages

-

1

The best cavity design. -

2

All hydraulic operation. -

3

Robust and reliable design for hard stone crushing. -

4

High reduction efficiency with the lowest cost. -

5

Simply maintenance and convenient in operation.

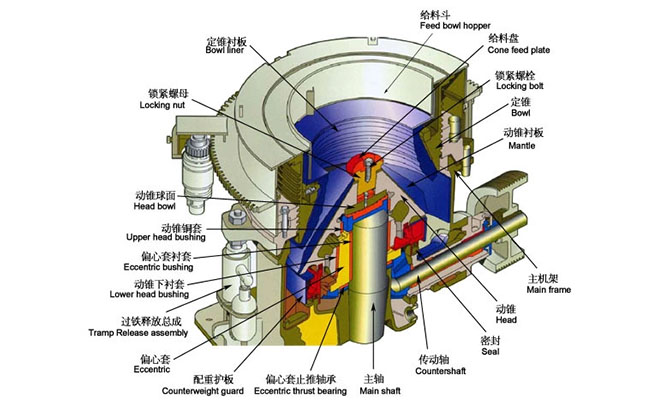

Working

The hydraulic cone crusher consists of a frame, transmission, hollow eccentric shaft, bowl-shaped bearing, crushing cone, springs and hydraulic pressure station to adjust the discharge opening. During operation, the motor drives the eccentric shaft housing to rotate through a horizontal axis and a bevel gear pair. The crushing cone axis oscillates with the strength of the eccentric shaft housing, so that the surface of the crushing wall is close to the wall of the roll mortar from time to time. In this way, the ores and rocks will be pressed, bent and crushed.

Technical Parameters

| Model | Crushing cavity type | Standard Type | Short-head Type | Power (KW) | Capacity (t/h) | ||

| Feeding inlet size (mm) | Min. Discharging size (mm) | Feeding inlet size (mm) | Min. Discharging size (mm) | ||||

| XHP-100 | C Coarse | 95 | 13 | 77 | 10 | 75-110 | 60-180 |

| M Medium | 65 | 14 | 58 | 6 | |||

| F1 Fine | 48 | 11 | 26 | 6 | |||

| F2 Extra Fine | 10 | 5 | |||||

| XHP-200 | C Coarse | 185 | 19 | 76 | 10 | 132-200 | 90-250 |

| M Medium | 125 | 17 | 54 | 6 | |||

| F1 Fine | 95 | 13 | 23 | 6 | |||

| F2 Extra Fine | 10 | 5 | |||||

| XHP-300 | C1 Extra Coarse | 230 | 25 | 180-250 | 115-440 | ||

| C2 Coarse | 210 | 20 | 75 | 10 | |||

| M Medium | 150 | 15 | 50 | 8 | |||

| F1 Fine | 105 | 10 | 20 | 6 | |||

| F2 Extra Fine | 20 | 6 | |||||

| XHP-400 | C1 Extra Coarse | 295 | 30 | 280-355 | 140-630 | ||

| C2 Coarse | 250 | 25 | 90 | 10 | |||

| M Medium | 195 | 20 | 50 | 8 | |||

| F1 Fine | 110 | 14 | 40 | 6 | |||

| F2 Extra Fine | 30 | 6 | |||||

| XHP-500 | C1 Extra Coarse | 330 | 30 | 355-450 | 175-790 | ||

| C2 Coarse | 285 | 25 | 90 | 13 | |||

| M Medium | 200 | 20 | 55 | 10 | |||

| F1 Fine | 133 | 16 | 40 | 8 | |||

| F2 Extra Fine | 35 | 6 | |||||

| XHP-800 | C1 Extra Coarse | 353 | 32 | 550-630 | 260-1200 | ||

| C2 Coarse | 297 | 32 | 155 | 13 | |||

| M Medium | 267 | 25 | 92 | 10 | |||

| F1 Fine | 219 | 16 | 33 | 6 | |||

| F2 Extra Fine | 40 | 6 | |||||

Send us a message

If you need our products please write down any questions, we will reply as soon as possible.