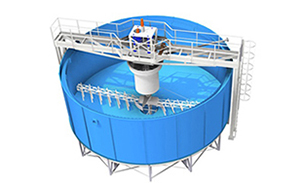

Hydrocyclone Group

- Capacity

- 10-524 m3 /h

- Separation Particle Size

- 25-130 μm

- Application Fields

- Separating and removing heavy mud and sand of coarse particles and sometimes for dehydration of slurry

Description

-

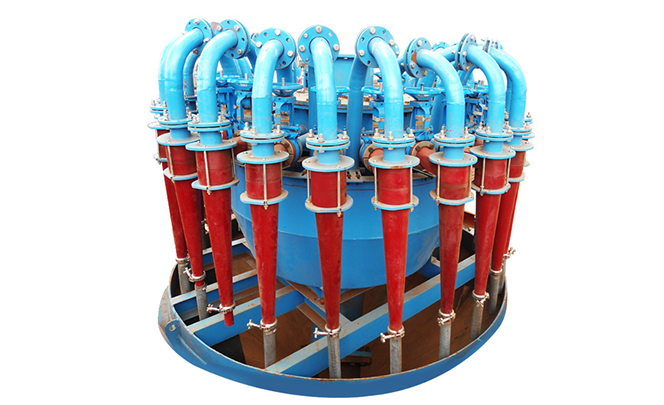

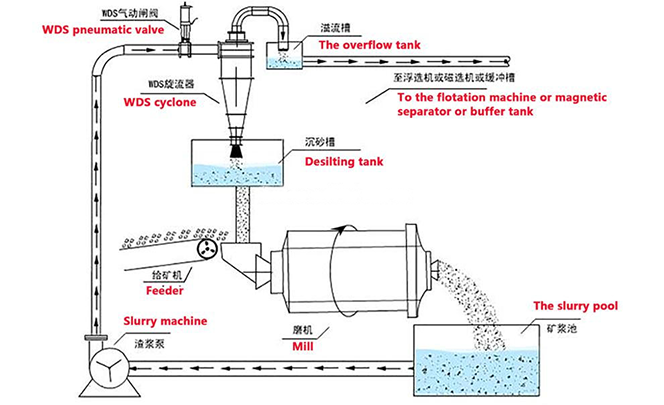

Hydrocyclone is used for separating and removing heavy mud and sand of coarse particles and sometimes for dehydration of slurry. The Hydrocyclone separator has two types of pressure type and gravity type made up of either cylindrical structure or metal pipe. Slurry is fed through the top of the structure (or metal pipe) by means of pressure or gravity along the tangent line. Coarse and thick particulate matters are thrown to the wall, rotated down and discharged together with the concentrated liquid formed under the action of centrifugal force. Small particulate matters are discharged together with secondary upward vortex after rotated to some extent. Hydrocyclone / cyclone filter is mainly used for classification, separation, concentration and desliming in the mineral mining industry. When the hydrocyclone is used as a classifier, it is mainly used to form a grinding and classification system with a mill; when it is used as a deslimer, it can be used for desliming in a gravity concentrator; when it is used as a concentrating and dewatering device, it can be used to concentrate ore dressing tailings and send them to fill underground mining tunnels. The hydrocyclone sand separator has no moving parts, simple structure, large capacity per unit volume, small area, high classification efficiency (up to 80% ~ 90%), fine classification granularity, low cost, and low material consumption.

Advantages

-

1

Simple structure and operation,safe performance and no maintenance; -

2

Compared with enlarged pipe and baffle box desanding equipment,it is of small size,big capacity and occupation-saved; -

3

To remove the sand from water in continuous water supplying; -

4

It aviod secondary pollution with other desanding equipment,also with high desanding efficiency;

Working Principle

The working principle of the cyclone is mainly centrifugal sedimentation. When the two-phase (or three-phase) mixture to be separated enters the cyclone at a certain pressure from the feeding port of the cyclone, a strong three-dimensional elliptical strong rotating shear is generated. Cut turbulent motion. Due to the different density of the particles, the centrifugal force, centripetal buoyancy, and fluid drag force are different. Due to centrifugal sedimentation, most of the coarse particles (or heavy phases) are discharged through the swirler bottom outlet, and most of the fine particles ( Or light phase) discharged from the overflow pipe to achieve separation and classification.

Technical Parameters

| Specification | Capacity(m3 /h) | Separation Particle Size (μm) | Diameter of Overflow Outlet (mm) | Diameter of Spigot (mm) | Inlet Pressure (MPa) |

| 150 | 10.0-23.0 | 25-74 | 30-50 | 8.0-20.0 | 0.060-0.15 |

| 200 | 17-38 | 28-80 | 40-65 | 16-32 | 0.060-0.15 |

| 250 | 24-53 | 30-82 | 65-100 | 16-40 | 0.060-0.15 |

| 300 | 40-100 | 36-90 | 65-120 | 20-40 | 0.060-0.15 |

| 350 | 56-118 | 40-100 | 80-120 | 30-70 | 0.060-0.15 |

| 375 | 74-157 | 42-105 | 90-135 | 30-70 | 0.060-0.15 |

| 450 | 90-192 | 44-110 | 100-150 | 30-70 | 0.060-0.15 |

| 500 | 128-300 | 50-115 | 130-220 | 35-100 | 0.060-0.15 |

| 610 | 200-468 | 57-125 | 160-260 | 65-110 | 0.060-0.15 |

| 660 | 237-524 | 60-130 | 180-280 | 80-150 | 0.060-0.15 |

Send us a message

If you need our products please write down any questions, we will reply as soon as possible.