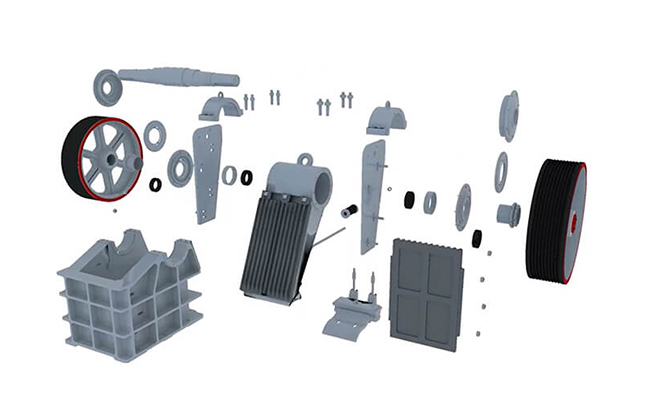

Jaw Crusher

- Capacity

- 0.5~700t/h

- Improvement

- Our Jaw crusher improves the traditional specification of crushing chamber by adopting high speed swing jaw and cambered jaw plate.

Description

- It is applied to fine crushing of various material of which compressive strength is less than or equal to 320Mpa, is applied to relatively small feeding material granularity and relatively small discharging gate, and is fitted for the secondary crushing. Our jaw types of crusher with high production capacity, large reduction ratio and high crushing efficiency.

Advantages

-

1

Model for the latest products, a wide range of applications, with a compact structure, long service life, and high work efficiency. -

2

Adjustable for easy wear parts, Easy replacement of wear and spare parts. -

3

High capacity, less costly and Easy to install. -

4

The machine has a large crushing ratio, uniform product size, simple structure, convenient maintenance, can crush the compressive strength of a variety of materials is not more than 320 MPa, is the first choice for primary crushing equipment. -

5

First-class technology, reliable pre-sale customer service quality. The products meet European CE certification standards.

Working

The electromotor drives the belt and pulley to make the movable jaw move back and forth, up and down through the eccentric shaft. The raw material is squashed or splitt when movable jaw plate moves towards fixed jaw together with movable jaw. When movable jaw and movable jaw plate turn back by eccentric shaft and spring, the raw material, which is squashed or split before discharges from the bottom outlet under jaw plate. The bulk-production comes true while electromotor rotates continuously and the movable jaw crushes and discharges the raw material periodically.

Technical Parameters

| Type | Model | Inlet Dimension (mm) | Outlet Dimension (mm) | Max. Feed Size (mm) | Capacity (t/h) | Rotating Speed of Eccentric Wheel (r/min) | Motor Power (kW) | Overall Dimension (mm) | Weight (kg) |

| Ordinary Crushing | PE100X150 | 100X150 | 5~20 | 80 | 0.5 ~2 | 300 | 2.2 | 525X535X605 | 230 |

| PE150X250 | 150X250 | 10 ~40 | 125 | 2~6 | 300 | 5.5 | 875X745X935 | 1100 | |

| PE200X350 | 200X350 | 10 ~50 | 160 | 6~10 | 300 | 7.5 | 1080X1060X1088 | 1600 | |

| PE250X400 | 250X400 | 20 ~60 | 210 | 8~26 | 300 | 15 | 1108X1090X1392 | 2396 | |

| PE250X400 | 8~16 | 1430X1316X1296 | 2800 | ||||||

| PE250X500 | 250X500 | 20 ~80 | 210 | 13 ~45 | 300 | 18.5 | 1360X1450X1440 | 3100 | |

| PE250X500 | 13 ~21 | 1425X1420X1417 | 3300 | ||||||

| PE400X600 | 400 X600 | 40~100 | 350 | 25 ~64 | 275 | 30 | 1650X1748X1520 | 5800 | |

| PE400X600 | 14 ~36 | 1716X1736X1653 | 6500 | ||||||

| PE500X750 | 500X750 | 50120 | 400 | 30 ~80 | 275 | 45 | 1900X1876X1821 | 9000 | |

| PE500X750 | 250 | 1980X2024X1920 | 12000 | ||||||

| PE600X900 | 600 X900 | 75 ~200 | 480 | 56~192 | 250 | 75 | 2280X2245X2320 | 16700 | |

| PE600X900 | 2280X2245X2320 | 14500 | |||||||

| PE750X1060 | 750X1060 | 80~235 | 630 | 108~256 | 250 | 90 | 2450X2472X2795 | 28000 | |

| PE900X1200 | 900X1200 | 95~265 | 750 | 186~398 | 200 | 110 | 3335X3182X3025 | 50000 | |

| PE1100X1400 | 1100X1400 | 150~300 | 950 | 250~600 | 193 | 132 | 3900X3040X3875 | 70000 | |

| PE1200X1500 | 1200X1500 | 160~320 | 1000 | 280~700 | 190 | 160 | 3800X3040X4150 | 82000 | |

| Fine Crushing | PEX150X750 | 150X750 | 18 ~48 | 120 | 8~25 | 320 | 15 | 1210X1572X1045 | 2800 |

| PEX150X750 | 10 ~40 | 1240X1586X1025 | 3500 | ||||||

| PEX200X1000 | 200 X1000 | 20~55 | 160 | 12 ~50 | 330 | 22 | 1860X1385X1200 | 5200 | |

| PEX250X750 | 250X750 | 20 ~60 | 210 | 10 ~45 | 320 | 30 | 1751X1400X1515 | 4900 | |

| PEX250X1000 | 250X1000 | 20 ~50 | 210 | 15 ~50 | 330 | 30 | 1550X1990X1370 | 6500 | |

| PEX250X1000 | 1650X1958X1460 | 6800 | |||||||

| PEX250X1200 | 250X1200 | 20 ~60 | 210 | 20 ~60 | 320 | 45 | 1650X2170X1465 | 9000 | |

| PEX300X1300 | 300X1300 | 25 ~65 | 250 | 20 ~80 | 330 | 55 | 1980X2456X1740 | 11500 |

Send us a message

If you need our products please write down any questions, we will reply as soon as possible.