Jigger

- Capacity

- 1~25t/h

- Improvement

- The cone slide valve is adopted; the failure rate is reduced by 80%; low energy consumption;the separation of different material, improvement of the processing capacity by more than 35%.

Description

- Introduction

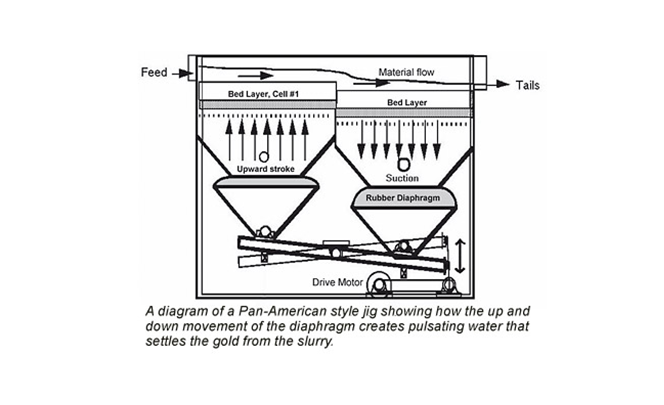

- A jigging machine realizes the separation of light and heavy mineral by the different sedimentation speed in vertical alternating water flow.

Advantages

-

1

Stroke and jig frequency are easy to adjust; -

2

The advanced frequency conversion speed control technology is convenient to operate and manage; -

3

Small cover area, high processing capacity per unit area.

Structure

Diaphragm Jigger is divided into two kinds of models including left-hand machine and right-hand jig cover. With the fixed sieve, the jig is suitable for metal ore classification such as placer contained tungsten and gold, tin concentration ore. This jig can be used not only for classification of fine-grained materials but also for that of raw materials with the largest size of 6-8 mm, but in the individual case of placer classification, the largest size is up to 12 mm.

Technical Parameters

| Item & Parameters & Model | Jigging Chamber | Diaphragm | Feed Size (mm) | Adding Water Yield Under Screen (m3/t) | Water Pressure (MPa) | Handling Capacity (t/h) | Motor Power (kW) | Dimension (mm) | Weight (kg) | ||

| Shape | Area (m2) | Stroke (mm) | Jig Frequency (time/min) | ||||||||

| JT-0.57 | Trapezoid | 0.57 | 8.5 ~12 10 ~17 12 ~21 | 80~180 | <6 | 1~2 | ≥ 0.05 | 1.5 ~3 | 1.5 | 1550X780X1530 | 610 |

| JT1-1 | Trapezoid | 1.04 | <10 | 2~3 | 2.5 ~5 | 2.2 | 2270X1110X1890 | 900 | |||

| JT2-2 | Rectangle | 2.28 | <10 | 2~4 | 5~10 | 3 | 3225X1550X2050 | 1640 | |||

| JT3-1 | Trapezoid | 3 | 12 ~30 | 50~125 | <10 | 3~6 | ≥ 0.05 | 7.5 ~15 | 5.5 | 2745X2000X3030 | 3085 |

| JT4-2 | Rectangle | 4 | 25 ~57 | <25 | 4~8 | 8~20 | 7.5 | 4240X1990X2750 | 3098 | ||

| JT4-2A | Rectangle | 4 | 25 ~57 | <25 | 4~8 | 8~20 | 4X2 | 4240X1990X2750 | 3500 | ||

| JT5-2 | Trapezoid | 4.86 | 12 ~30 | <10 | 3~6 | 12 ~25 | 7.5 | 3600X2000X2600 | 4500 | ||

Send us a message

If you need our products please write down any questions, we will reply as soon as possible.