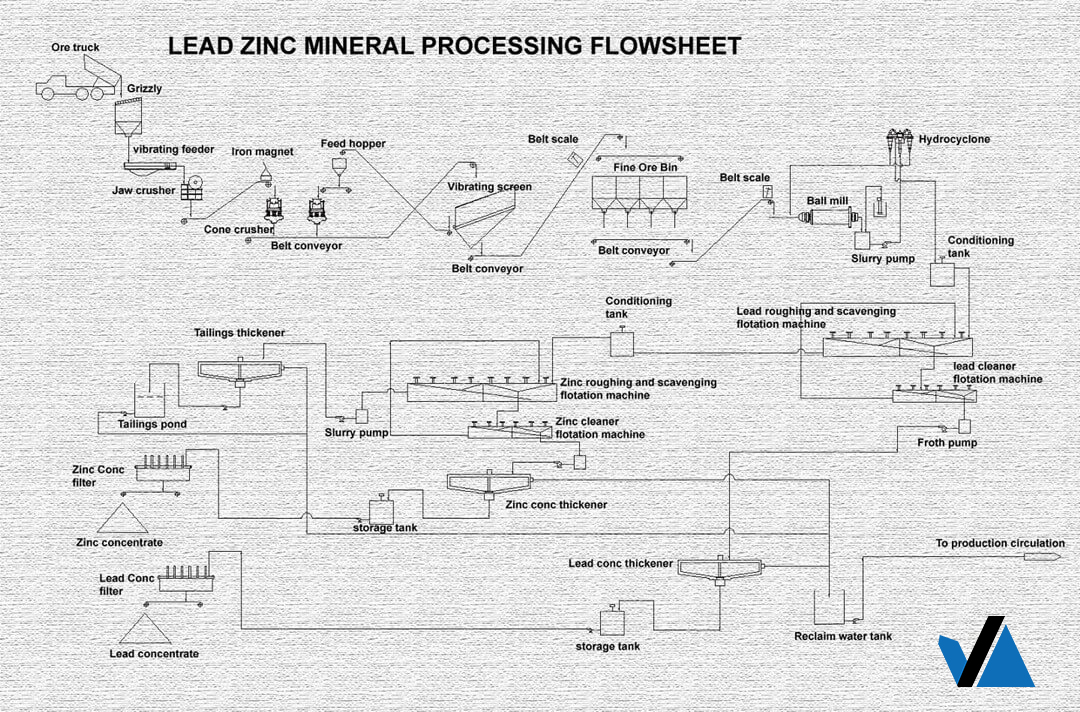

Lead-Copper-Zinc Polymetallic Ore Dressing Process

According to the high sulfur and complex characteristics of copper-lead-zinc ore, a combined flotation-concentrate regrinding process is generally used. In the lead-zinc ore beneficiation process, the equipment usually selected is copper-lead-zinc mixed flotation machine and high-efficiency stirring tank. This can reduce the cost of beneficiation and has the characteristics of high efficiency and environmental protection.

Application

Copper-lead-zinc deposit is produced in the Paleozoic metamorphic volcanic rock series, and the ore-bearing wall rock is quartz keratophyte tuff. The main types of ore include massive copper-lead-zinc ore, disseminated copper-lead-zinc ore and pyrite ore. The structure is complex, and the mixed flotation-concentrate regrind process is generally adopted.Aiming at the characteristics of copper, lead, and zinc polymetallic sulfide ore that are easy to flotation and difficult to separate, and the embedded particle size is extremely uneven, the priority flotation copper-regrinding-selected copper-copper flotation tailings lead-reselection Process.This process does not need to grind all the raw ore finely, which saves the cost of grinding. At the same time, the regrind of the concentrate makes the copper-lead concentrate further monomer dissociation, and has a good de-drug effect, creating favorable conditions for the separation of copper-lead.

In addition, the medicament system is strictly implemented in the rough selection section to control the amount of medicament, reduce multiple cycles and unnecessary loss, make full use of the secondary enrichment effect of foam, and flush the concentrate foam to reduce the amount of foam in the foam. Impurities, to achieve the purpose of enhanced flotation.

There are many cases of Henan Victory copper-lead-zinc ore dressing process. Welcome to visit our company!

A copper-lead-zinc ore beneficiation plant in Southwest China, using the technical advantages of optimization and mixed flotation, combined with the characteristics of the ore, adopted partial optimization flotation to reduce unnecessary losses. The final lead concentrate grade reached 62.31%; the recovery rate was 84.51%.

If you need our products please write down any questions, we will reply as soon as possible.