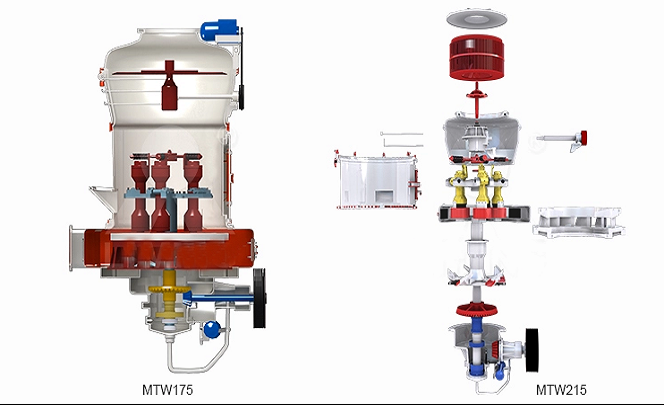

MTW Grinding Mill

- Capacity

- 3.5-45T/h

- Input Size

- 0-50mm

- Processed Materials

- Limestone, calcite, barite, dolomite, potassium feldspar, marble, talcum, gypsum, kaolin, bentonite, medical stone, rock phosphate, manganese ore, iron ore, quartz, active carbon, carbon black, ceramic, clinker, ect.

Description

- Introduction

- MTW Grinding Mill--- the latest type of Raymond Mill, has become one of the most advanced grinding mills in the world with its so many intellectual properties like bear-gear drive, inner oil lubricating system, arc air channel, etc.

Advantages

-

1

Linkage supercharging device of rollers, stable operation and advanced productivity; -

2

Bevel gear overall drive, less energy loss, higher efficiency; -

3

With reliable and advanced technology of Inner automatic Thin-oil lubricating system; -

4

Arc air channel, less air flow loss, better material fluidity; -

5

Special design of rollers and ring, replaceable curved shovel edge, higher efficiency and lower cost-in-use; -

6

No resistance snail shell; -

7

Adjustable output size, efficient powders production; -

8

High efficiency and precision of powders collection; -

9

Humanized design, easy to use; -

10

Environmental protection.

Structure

First, raw material should be crushed by the jaw crusher to the size specified, and then the crushed stuff is elevated into a hopper from which the stuff is loaded, through the vibrating feeder, evenly and continuously into the grinding chamber for power-processing. After this, the ground stuff is carried by the air into the separator for screening. The fine powder are blow into the cyclone collector and are poured out through the output-powder valve as the final products and the rough stuff after the screening will be recycled back into the grinding chamber for regrinding. The set's airflow system is closely sealed up and circulated under condition of negative pressure.

Technical Parameters

| Items | MTW110 | MTW138 | MTW138Z | MTW175 | MTW175Z | MTW215 | MTW215Z |

| Q'ty of Rollers(PCS) | 4 | 4 | 4 | 5 | 4 (5) | 5 | 5 |

| Major diameter of roller(mm) | Ф360×190 | Ф460x240 | Ф460×240 | Ф520x280 | Ф580×280 (520×280) | Ф640x320 | Ф640×320 |

| Inner Diameter of Ring (mm) | Ф1100×190 | Ф1380×240 | Ф1380×240 | Ф1750×280 | Ф1750×280 | Ф2150×320 | Ф2150×320 |

| Main mill Rotating speed (r/min) | 120 | 96 | 96 | 75 | 75 | 65 | 55-70 |

| Feeding size (mm) | <30 | <35 | <30 | <40 | <35 | <50 | <40 |

| Finished Powder Sizes (mm) | 1.6-0.045 the finest 0.038 | 1.2-0.05 | |||||

| Capacity (t/h) | 3.5-10 | 6-15 | 6-20 | 11-25 | 11-35 | 20-50 | 20-50 |

| Overall Dimension (L×W×H)(mm) | 8425×7933 ×8642 | 10920×9655 ×10227 | 10920×9470 ×10227 | 12095×10023 ×9916 | 12195×9555 ×9916 | 14500×11200 ×10400 | 14.957×12493 ×11560 |

| Weight (t) | 18 | 28.5 | 28.5 | 46 | 46 | 96 | 97.0122 |

Send us a message

If you need our products please write down any questions, we will reply as soon as possible.