Magnetic Separator

- Capacity

- 10t/h-280t/h

- Rotation Speed

- 9.1-14.25r/min

- Improvement

- Magnetic system materials adopt the NdFeB with high magnetic energy product and high coercivity, strong magnetic density and high affect depth; the surface of the cylinder is lined with Xinhai wear-resistant rubber.

Description

- Introduction

- A wet permanent magnetic separator for separating strong magnetic minerals that is suitable for wet magnetic separation of magnetite, pyrrhotite, roasted ore, ilmenite and other materials. It is also used for iron removing operations of coal, non-metallic minerals, building materials and other materials.

Advantages

-

1

Magnetic system is compounded of ferrite and permanent magnets, the average magnetic induction intensity of cylinder surface is 100~600mT; -

2

The same cylinder can be equipped with three types of tank adapting to different dressing process; -

3

Small floor space, good separation for magnetic minerals, reduce the load of next process.

Structure

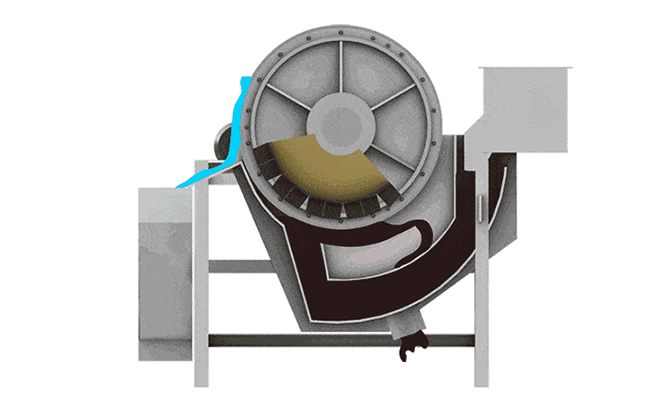

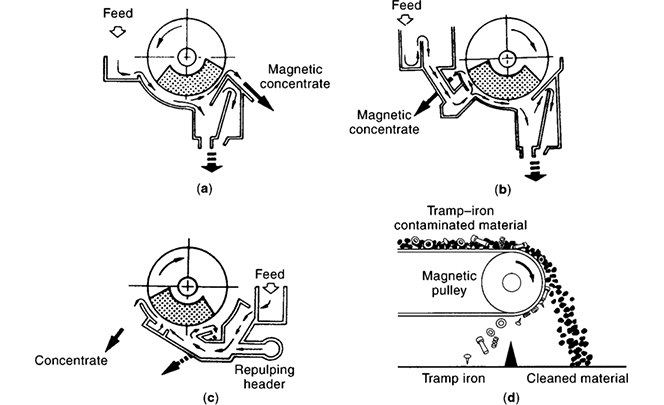

Permanent magnetic drum separators have 3 kinds including downstream type, counter flow type and semi- counter flow type according to the difference of base structures.

Downstream type permanent magnetic drum separator: slurry flows in the same direction with the drum.

Counter flow type permanent magnetic drum separator: slurry flows over against the drum, which create great conditions for cleaning of non magnetic ores. The non magnetic ores approach the clean surface of the drum and the magnetic ores can be absorbed in the strongest magnetic field.

Semi-counter flow type permanent magnetic drum separator: slurry is fed into the cavity from the bottom of the drum, and the magnetic ores fall into the concentrate tank after reaching a certain height, while the non magnetic ores will enter into tailings tank along with slurry in the opposite direction with drum..

Technical Parameters

| Model | Shell diameter | Shell lenght | Shell rotation | Feeding size | Processing capacoty | Power(kw) |

| (mm) | (mm) | speed(r/min) | (mm) | (t/h) | ||

| CTB6012 | 600 | 1200 | <35 | 2-0 | 44489 | 1.5 |

| CTB6018 | 600 | 1800 | <35 | 2-0 | 15-30 | 2.2 |

| CTB7518 | 750 | 1800 | <35 | 2-0 | 20-45 | 2.2 |

| CTB9018 | 900 | 1800 | <35 | 3-0 | 40-60 | 3 |

| CTB9021 | 900 | 2100 | <35 | 3-0 | 45-60 | 3 |

| CTB9024 | 900 | 2400 | <28 | 3-0 | 45-70 | 4 |

| CTB1018 | 1050 | 1800 | <20 | 3-0 | 50-75 | 5.5 |

| CTB1021 | 1050 | 2100 | <20 | 3-0 | 50-100 | 5.5 |

| CTB1024 | 1050 | 2400 | <20 | 3-0 | 60-120 | 5.5 |

| CTB1218 | 1200 | 1800 | <18 | 3-0 | 80-140 | 5.5 |

| CTB1224 | 1200 | 2400 | <18 | 3-0 | 85-180 | 7.5 |

| CTB1230 | 1200 | 3000 | <18 | 3-0 | 100-180 | 7.5 |

| CTB1530 | 1500 | 3000 | <14 | 3-0 | 170-280 | 11 |

Send us a message

If you need our products please write down any questions, we will reply as soon as possible.