Magnetite Ore Dressing Process

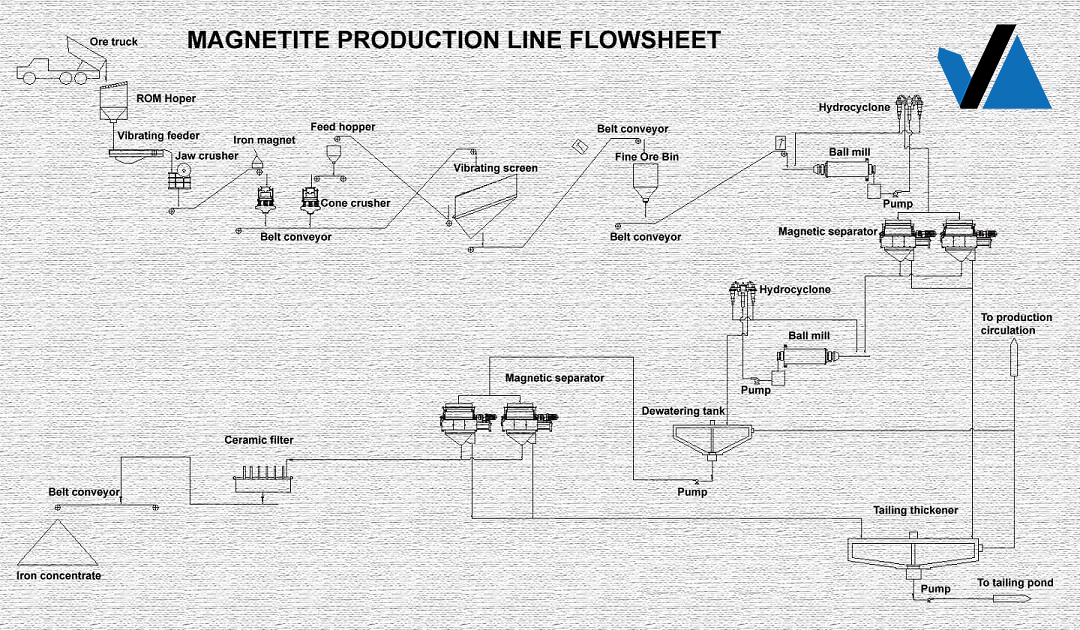

The magnetite beneficiation production line is common in the beneficiation process, and it is also the more commonly used one. It has the advantages of simple and easy operation, reasonable process, economic investment, economy and environmental protection, and high recovery rate. The process of the magnetite beneficiation production line is roughly as follows: hopper ---- feeder ---- jaw crusher ---- cone crusher ---- ball mill ---- spiral classifier- ---magnetic separator.

Application

The magnetite ore dressing process is suitable for wet magnetic separation of magnetite, pyrrhotite, roasted ore, ilmenite and other materials with a particle size of less than 3mm. Iron removal from coal, non-metallic minerals, building materials and other materials.According to the material characteristics of magnetite, magnetic separation is a more effective method for beneficiation of magnetite. In order to improve the technical index of magnetite dressing, Henan Victory has designed a magnetite dressing production line specially for the magnetite dressing property. The equipment and beneficiation process needed in the magnetite dressing production line are briefly introduced below.

The mined magnetite is sent to the jaw crusher by a vibrating feeder for primary crushing, and then it is finely crushed by a cone crusher, and the magnetite is crushed to a qualified fineness by a bucket elevator , The ore feeder is evenly fed into the ball mill for grinding, and the magnetite after being ground by the ball mill enters the next step of classification process. The spiral classifier classifies the ore mixture according to the working principle of the different specific gravity of the magnetite mineral particles resulting in different precipitation speeds. The classified mixture enters the magnetic separator. Due to the difference in the specific magnetic susceptibility of various minerals, The magnetic substance of the mixture can be effectively separated. Since the separated ore contains a large amount of water, it needs to be preliminarily concentrated by a thickener, and then dried by a dryer to obtain a dried ore concentrate.

Features of the magnetite ore dressing process

1. The processing capacity of magnetite is relatively large, the daily output can reach more than 1,800 tons, and the beneficiation efficiency is also relatively high, which is three times that of the ordinary beneficiation production line.

2. The amount of waste of resources and electricity consumption is relatively small, which saves water resources and improves the comprehensive recycling rate of ore.

3. The beneficiation process is simple, the degree of automation is relatively high, and the operation is relatively easy, which reduces the labor investment cost for the enterprise.

4. It is not easy to malfunction during operation, the cooperation between various equipment is better, and the operation is stable and safe.

5. The grade of concentrate obtained is relatively high, and the beneficiation index is greatly improved.

6. Equipped with corresponding dust-proof and silencer devices to avoid the pollution of the mining area environment caused by dust and noise, and the low-carbon environmental protection effect is more significant.

If you need our products please write down any questions, we will reply as soon as possible.