Manganese Ore Dressing Process

Manganese ore is fine-grained or fine-grained, and contains a considerable amount of high phosphate ore, high iron ore, and co- (associated) beneficial metals, making it difficult to beneficiate. Commonly used manganese ore beneficiation methods are mechanical separation (including washing, screening, gravity separation, strong magnetic separation and flotation), as well as pyroconcentration, chemical beneficiation, etc. Commonly used equipment is introduced: vibrating feeder, jaw crusher, vibrating screen, feeder, ball mill, spiral classifier, mixing barrel, flotation machine, etc.

Application

The beneficiation of weakly magnetic minerals, such as hematite, limonite, ilmenite, wolframite, tantalite, etc; Iron removal and purification of non-metallic minerals, such as: quartz, feldspar, nepheline, fluorite, sillimanite, spodumene, kaolin, etc.The following describes the steps in the manganese ore beneficiation method:

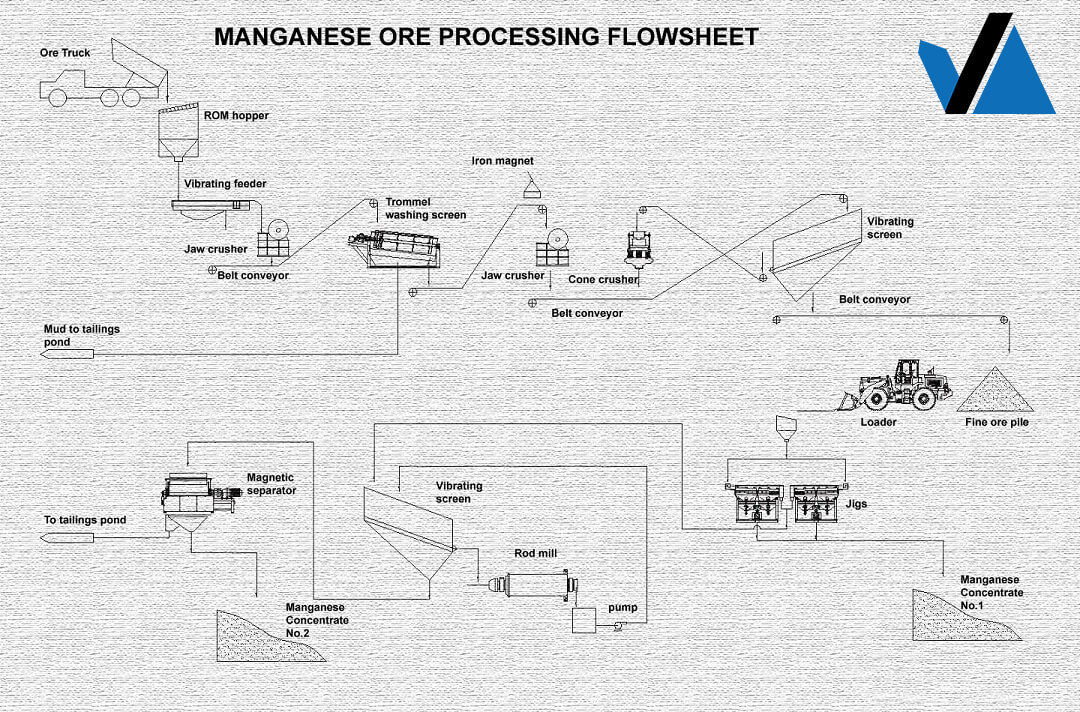

Washing and screening

Washing is the use of hydraulic washing or additional mechanical scrubbing to separate the ore from the mud. Commonly used equipment is ore washing screen, cylinder washing machine and trough washing machine. Ore washing operations are often accompanied by screening, such as washing directly on the vibrating screen or sending the ore (clean ore) obtained by the washing machine to the vibrating screen for screening. Screening can be used as an independent operation to separate products of different particle sizes and grades for different purposes.

Re-election

At present, gravity separation is only used to separate manganese ore with simple structure and coarser grain size, especially suitable for manganese oxide ore with higher density. Commonly used methods are heavy medium beneficiation, jig beneficiation and shaker beneficiation.

The current process flow of manganese oxide ore is generally to crush the ore to 6 to 0 mm or 10 to 0 mm, and then group the ore, jigging for the coarse level, and sending to the shaker for the fine level.

Strong magnetic separation

Manganese minerals are weakly magnetic minerals and can be recovered in a strong magnetic field magnetic separator. Generally, the manganese grade can be increased by 4% to 10%. Because of its simple operation, easy control and strong adaptability, magnetic separation can be used for the separation of various manganese ore, and it has taken a dominant position in manganese ore beneficiation in recent years.

Strong magnetic-flotation

The strong magnetic separation-flotation method has better adaptability. The strong magnetic separator not only effectively removes the sludge, but also improves the flotation grade. The use of strong magnetic-flotation desulfurization can directly obtain comprehensive manganese concentrate products; the use of petroleum sulfonate instead of oxidized paraffin soap as a collector can enable the separation of the slurry at neutral and normal temperature, saving chemical consumption and energy consumption.

If you need our products please write down any questions, we will reply as soon as possible.