Molybdenum Ore Dressing Process

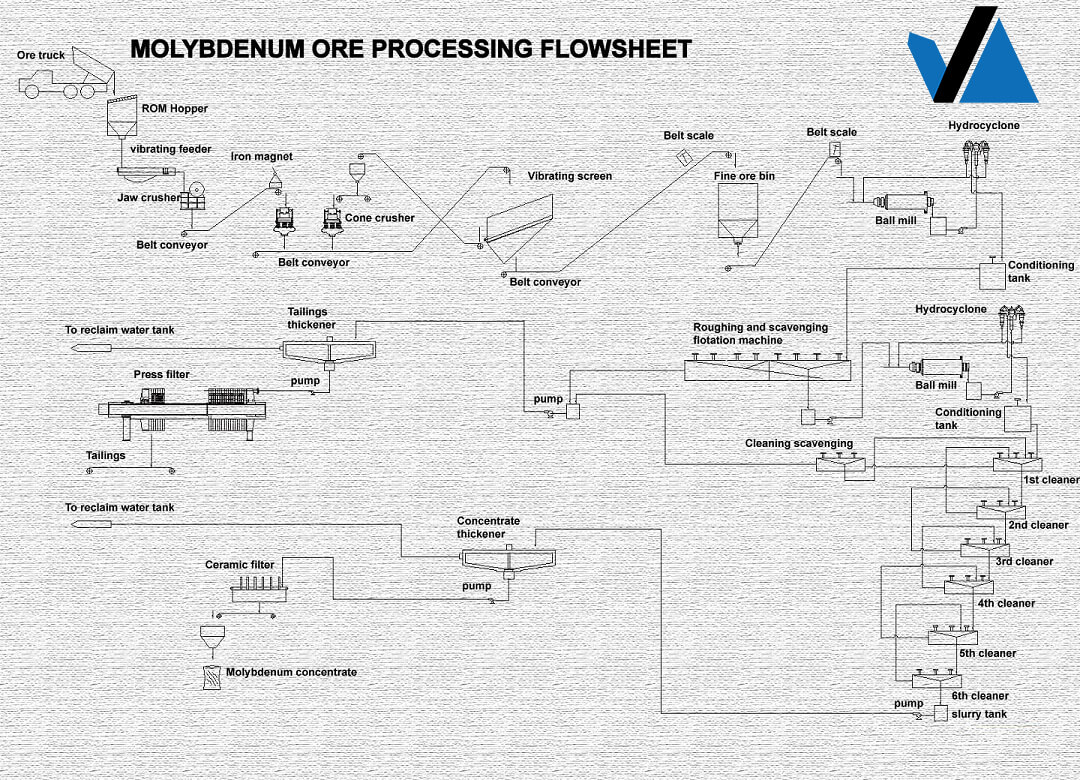

The molybdenum ore dressing process is mainly flotation, and the recovered molybdenum mineral is molybdenite. Sometimes in order to improve the quality of molybdenum concentrate and remove impurities, the molybdenum concentrate is subjected to chemical beneficiation. The molybdenum ore production line is mainly composed of jaw crushers, cone crushers, feeders, ball mills, classifiers, flotation machines, thickeners, filter presses and other equipment.

Application

Metal molybdenum has the advantages of high strength, high melting point, corrosion resistance, and wear resistance. In the metallurgical industry, molybdenum is used as an additive in the production of various alloy steels to improve its high-temperature strength, wear resistance and corrosion resistance. The main method of molybdenum beneficiation is flotation.The process flow of molybdenum ore dressing process is as follows:

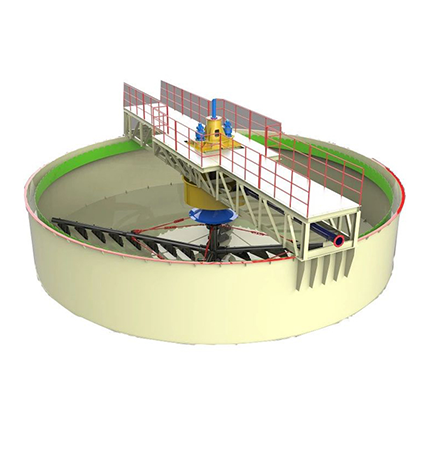

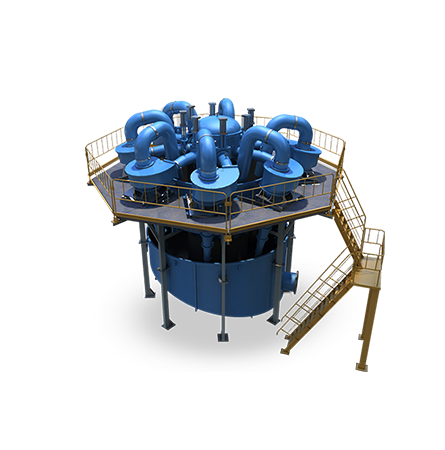

The mined ore is firstly crushed by a jaw crusher, and after being crushed by the crusher to a reasonable fineness, it is evenly sent to the ball mill through the elevator and feeder, and the ore is crushed and ground by the ball mill. The ore fines ground by the ball mill enter the next process: classification. The spiral classifier cleans and classifies the ore mixture by using the principle that the solid particles have different specific gravity and different precipitation speeds in the liquid. The washed and graded mineral mixture is uniformly stirred in a mixing tank and then sent to the flotation machine. According to different mineral characteristics, different corresponding flotation reagents are added to separate the desired minerals from other substances. In the new flotation machine, the environment for the dynamic collision of bubbles and ore particles and the static separation of the bubble particle combination is better, which is conducive to the separation of fine or fine molybdenum ore. In addition, the flotation machine realizes automatic control, so it is more suitable The selection of molybdenum ore. Mineral concentrates after flotation generally contain a lot of water, and a new type of high-efficiency thickener must be used to reduce the moisture of the concentrate to the required standard. All production links can be connected by conveyors and feeders.

If you need our products please write down any questions, we will reply as soon as possible.