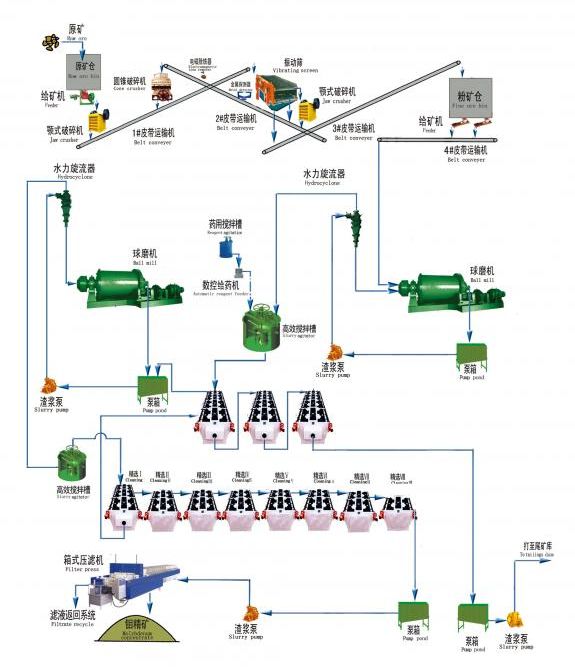

Nickel Ore Dressing Process

Nickel ore is mainly divided into copper-nickel sulfide ore and nickel oxide ore, and their beneficiation and processing methods are different. The most important method for beneficiation of copper-nickel sulfide ore is flotation, while magnetic separation and gravity separation are usually auxiliary methods. At present, most of the nickel oxide ore is crushed, screened and other processes are used to remove the large base rock with weak weathering degree and low nickel content in advance, and then adopt the smelting enrichment method.

Application

The nickel ore dressing process can be applied to copper-nickel ore or nickel oxide ore with pyrite and other gangues.The following mainly introduces the nickel ore dressing process. The flotation of copper-nickel ore has the following four basic processes:

Directly use priority flotation or partial priority flotation process:

when the copper content in the ore is much higher than the nickel content, this process can be used to select copper into a separate concentrate. The advantage of this process is that copper concentrate with lower nickel content can be directly obtained.

Mixed flotation process:

used to separate ores with copper lower than nickel, and the obtained copper-nickel mixed concentrate is directly smelted into high matte.

Mixing-optimal flotation process:

mixing flotation of copper and nickel from the ore, and then separating low-nickel-containing copper concentrate and copper-containing nickel concentrate from the mixed concentrate. After the nickel concentrate is smelted, high nickel matte is obtained, and the high nickel matte is then subjected to flotation separation.

Mixing-preferential flotation and reclaiming part of nickel from mixed flotation tailings:

when the flotability of various nickel minerals in the ore is very different, after the mixed flotation of copper and nickel, the tailings Further recover nickel-containing minerals with poor floatability.

Copper is a harmful impurity in nickel smelting, and the copper grade in copper-nickel ore has industrial recovery value. Therefore, copper-nickel separation technology is an important topic in copper-nickel ore beneficiation. Copper-nickel separation technology is divided into two types: copper-nickel mixed concentrate separation and high matte separation technology. Generally, the former is used for copper-nickel minerals with relatively coarse grain size and not closely interspersed with each other, and the latter is used for copper-nickel minerals with fine granularity and dense interspersion.

If you need our products please write down any questions, we will reply as soon as possible.