Phosphate Ore Dressing Process

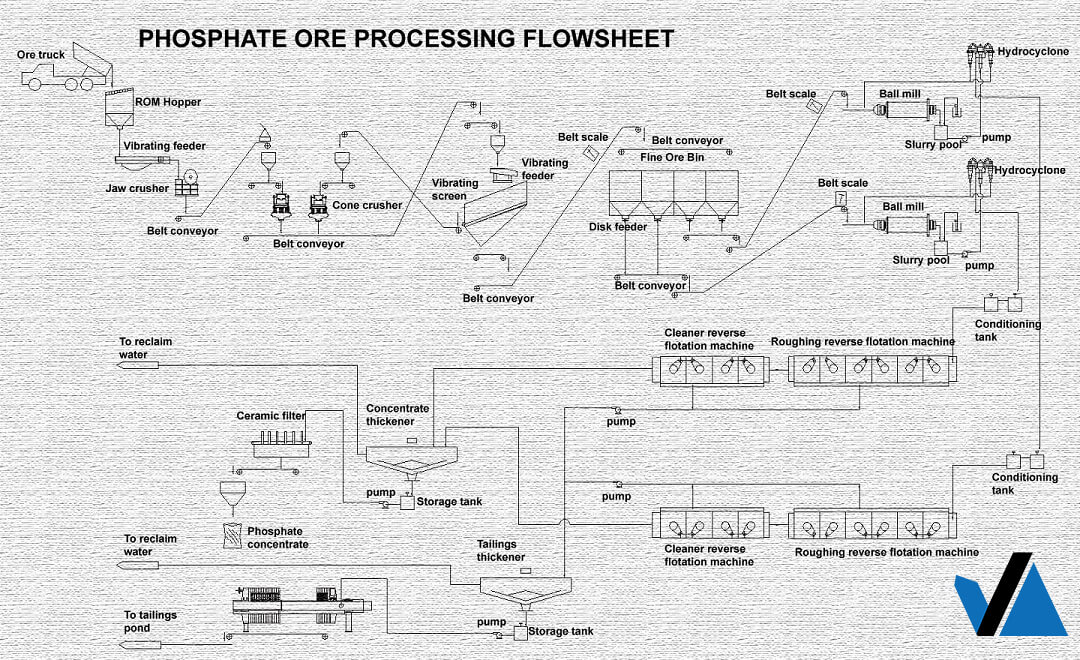

The main minerals of phosphate rock are apatite and collophanite, and the extraction of phosphate rock is mainly through these three steps: crushing and grinding-washing and classification-separation and extraction. Because of the difference in phosphorus, we need to use different extraction methods. Flotation purification is commonly used. According to the degree of difficulty of the ore, there are single positive flotation process, reverse flotation process, positive - negative flotation process and double reverse flotation process, etc.

Application

Phosphate rock has important uses in agriculture, medicine, matches, dyes, sugar, food, textiles, glass, ceramics, and national defense industries. Phosphate ore processing technology includes flotation, roasting and digestion, sludge scrubbing, reverse-positive flotation, heavy media, etc. Among these technologies, direct flotation, reverse flotation, scrubbing sludge, and heavy medium separation have been successfully applied.The goal of phosphate rock enrichment is to maximize the separation and removal of mineral impurities and to improve the grade and quality of the phosphate rock. The enrichment process as following:

Crushing

Reduce the particle size of the ore to dissociate the phosphate minerals from the impurity minerals. The phosphate minerals and impurity minerals in the phosphate rock are often cemented together in different degrees. They can only be dissociated when they are ground to a certain size. Determined by the particle size of phosphorus minerals and impurity minerals. This operation is often the basic step of phosphate rock enrichment.

Washing

Used to separate fine ore particles, such as phosphate ore mud, clay ore and fine-grained quartz. Because the wet ore mud often adheres to the phosphate rock and sometimes forms a mud mass, it must be dispersed by scrubbing and then separated. Water washing can also remove certain soluble substances, such as sodium chloride and free lime in calcined phosphate rock.

Classify

After crushing and washing, classification is often required. Commonly used classification equipment are wet screens, hydrocyclones and spiral classifiers.

Flotation

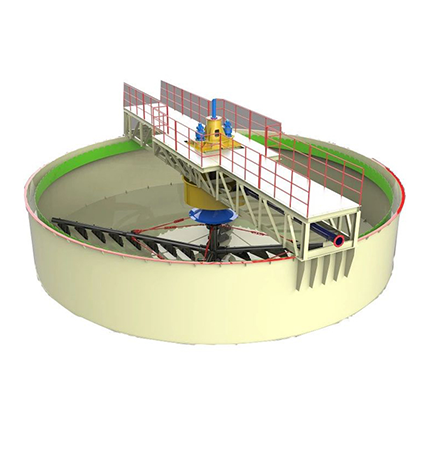

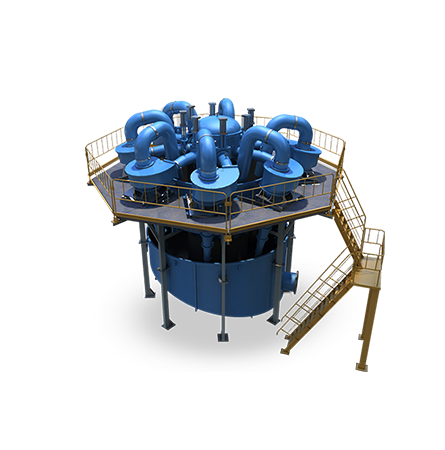

Using the different surface properties of phosphorus minerals and impurity minerals, the use of flotation agents to float the phosphorus minerals to achieve the purpose of separation, this operation is called positive flotation. The other is to float impurity minerals and sink phosphate minerals, which is called reverse flotation. In order to make the separation more effective, it is often necessary to add inhibitors to inhibit the floating of certain minerals. The ore pulp containing phosphorus minerals obtained from the flotation machine is thickened, filtered and dehydrated to obtain concentrate.

Magnetic separation

Use a magnetic separator to separate and remove the magnetic impurity minerals in the phosphate rock.

Photoelectric separation

The different colors of phosphorus minerals and impurity minerals are used to identify with photoelectric elements, and the compressed air jet is controlled to separate the phosphorus minerals from the impurity minerals.

Calcination

It is used to remove organic matter, carbon dioxide and a part of fluorine in phosphate rock. The calcination temperature is 400-1400℃ according to different purposes.

Heavy media separation

Using the different densities of phosphorus minerals and impurity minerals, choose a medium whose density is between the two, so that one mineral will float up in the medium and the other will sink to achieve the purpose of separation. Phosphate ore enrichment process depends on specific conditions.

If you need our products please write down any questions, we will reply as soon as possible.