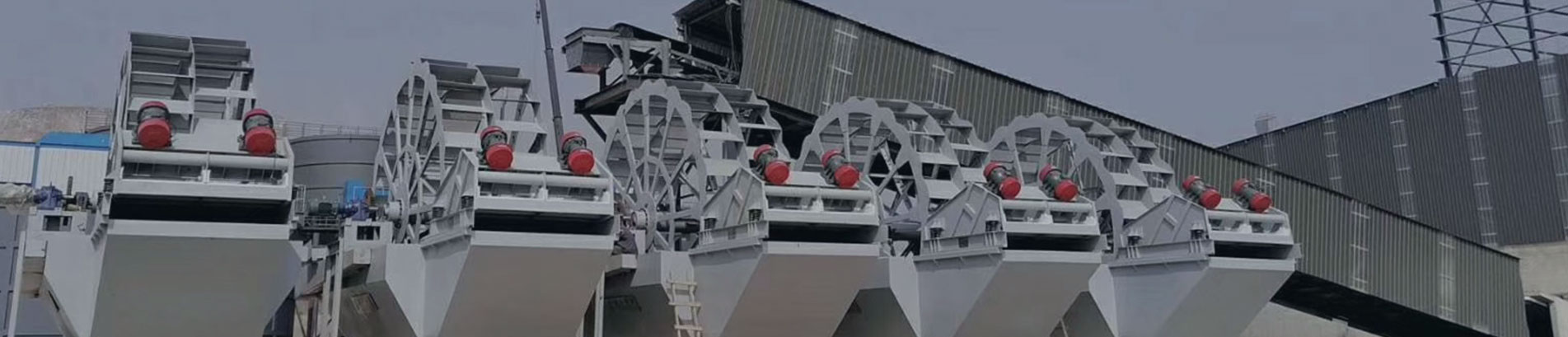

Silica Sand Scrubbing Machine

- Capacity

- 2-100t/h

- Improvement

- Silica sand scrubbing machine is a mechanical equipment designed and manufactured by our company according to production practice. It is used to scrub the slurry with a concentration of 68~70%, scrub the mud and sand on the ore, and create conditions for the beneficiation operation. It is also suitable for other scrubbing industries.

Description

- Silica sand scrubbing machine is mainly used for the dispersion of sludge, mineral surface impurities and scrub cleaning. They are generally used before or after sand screws in sand washing plant to scrub the surfaces of particulates, break down impurities, and remove it from competent aggregate material to reduce the product turbidity. We design singl and multiple cell attrition scrubber units for different scrubbing requirements of mineral materials.

Advantages

-

1

Simple structure, large volume and small area. The peripheral speed is low and the service life is long. The power consumption is small, the scrubbing and stirring intensity is strong, and the effect is good. -

2

The impeller is located above the "pulp precipitation zone", which is easy to start and has low starting power, which can reduce the labor intensity of the operator. -

3

The relative positions of the feeding, discharging and the motor of the double-tank scrubbing machine can be manufactured in different positions according to user needs. -

4

The light starting and small starting power greatly reduces the operator’s working intensity because of the impeller is above the pulp sedimentation zone. -

5

Large scrubbing intensity and good effect. The unique tank structure and impeller configuration increase the scrubbing strength by about 30% compared to the conventional scrubber of the same specification.

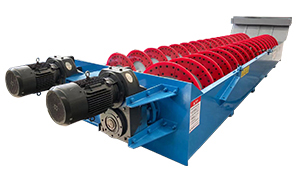

Structure

The slurry enters into the scrubber cavity through the feed pipe, and under the strong stirring effect of the impeller, the slurry produces violent turbulence. Minerals have a huge momentum in them, and produce intense friction and collision with each other. Impurity film wrapped in the surface of the mineral particles due to the intensity is not large, after friction and impact can easily be stripped out of the mineral surface. The mineral surface cement soaked in water and then through the strong mutual friction between the particles, the collision will be loose, broken solution, so as to achieve the separation of clay and mineral particles. These thin film impurities and clay break down and fall into the pulp, which can be separated after subsequent desliming. In the actual production process, but also according to the actual situation of the mineral add different agents.

Technical Parameters

| Model | Impeller diameter(mm) | Volume (m³) | Feeding size(mm) | Capacity (t/h) | Power (kw) | Weight (kg) | Dimension(mm) |

| YSC0.25-1 | 240 | 0.25 | ≤10 | 2-10 | 3 | 350 | 710*708*1310 |

| YSC0.25-2 | 240*2 | 0.25*2 | ≤10 | 2-10 | 3*2 | 660 | 1365*708*1310 |

| YSC0.5-1 | 320 | 0.5 | ≤10 | 5-20 | 5.5 | 450 | 922*886*1550 |

| YSC0.5-2 | 320*2 | 0.5*2 | ≤10 | 5-20 | 5.5*2 | 890 | 1761*886*1550 |

| YSC1-1 | 480 | 1 | ≤10 | 10-40 | 15 | 1400 | 1180*1142*2057 |

| YSC1-2 | 480*2 | 1*2 | ≤10 | 10-40 | 15*2 | 2410 | 2276*1142*2057 |

| YSC2-1 | 520 | 2 | ≤10 | 20-70 | 30 | 3300 | 1597*1597*2775 |

| YSC2-2 | 520*2 | 2*2 | ≤10 | 20-70 | 30*2 | 6210 | 3075*1597*2775 |

| YSC4-1 | 770 | 4 | ≤10 | 40-100 | 55 | 7500 | 1900*1752*3470 |

| YSC4-2 | 770*2 | 4*2 | ≤10 | 40-100 | 55*2 | 14560 | 3712*1752*3470 |

Send us a message

If you need our products please write down any questions, we will reply as soon as possible.