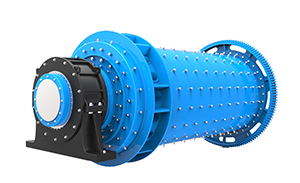

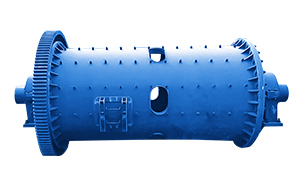

Raymond Mill

- Capacity

- 0.15–5.2 t/h

- Applicable Material

- Raymond mill, also known as raymond grinding mill, raymond roller mill and raymond grinder, is suitable for grinding non-flammable and non-explosive materials.The finished powder size can be adjusted between 30 and 425 mesh(0.613mm-0.044mm)

Description

- Introduction

- Raymond mill is the latest grinding mill, which is developed by our company's experts based on 48 years' R&D on grinding machine. It owns many independent patents property, such as overall prick gear drive, internal thin oil lubrication system, and arc-shaped air duct. All of these make it leading the trend of the milling industry in the world.

Advantages

-

1

Large volume of pulp circulation up to 2.5 times, favors the mineralization of the pulp, reagents and air; -

2

Large air suction volume, good dispersion effect; -

3

The reasonable circulation of mineral mud and solid particles suspend well, no sediment in the tank and no need to feed the mine when it stopped. -

4

Wide range of particle size and high ore selection recovery rate; -

5

Mechanical agitation; self-suction of air, but not mud; the ladder is required during processing (drop height: 300-400 mm); -

6

The VIC flotation cell can be combined with the model SF flotation cell as a flotation cell set: model SF as the suction cell and model VIC as the direct flow cell.

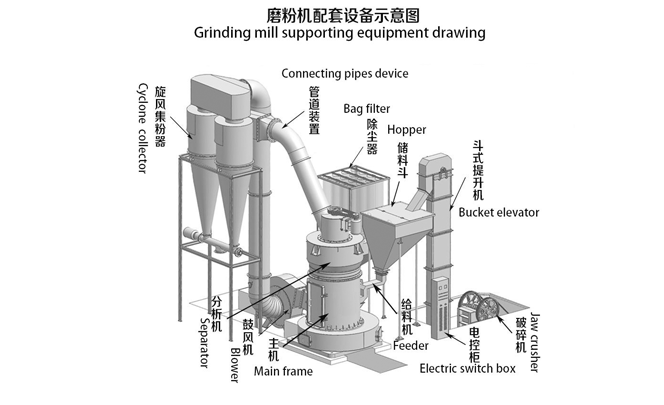

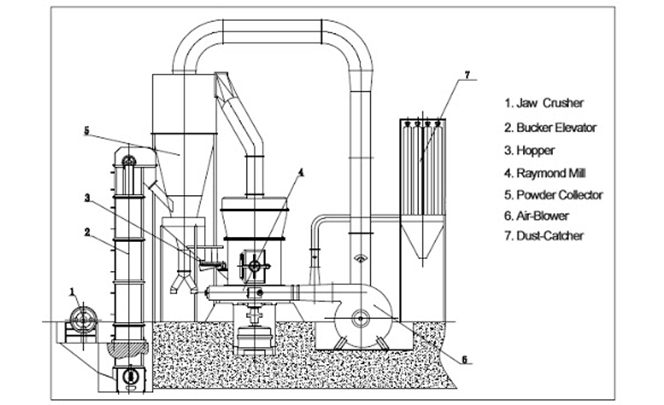

Structure

In the mainframe of raymond mill grinding machine, there are strong springs with pressure as high as1000-1500 kg equipped on the roller suspender. When Raymond Mill works, the roller rotates around the principal axis, and clings to ring under the effect of the strong spring and eccentricity. Its press is 1.2 times of Raymond mill under the same press condition, so the production is largely increased. When the materials are sent into the grinding chamber, they are brought to the space between the roller and ring and get grinded. Then the powder grinded will be blown into separator. The fine powder after departed with the air is discharged through the outlet as final product. The large-sized powder falls back for regrinding. The air will be back to the blower for repetition of the above process. The left air wil come to the bag filter to get cleaned. When the wear and tear between roller and the ring reaches certain degree, adjust the length of the strong spring,, so to keep the invariable pressure between the roller and the ring, to make sure the stable production and the fineness..

Technical Parameters

| Model | Grinding Roller | Grinding Ring | Feeding Size (mm) | Output Size (mm) | Capacity (t/h) | Motor Power (kw) | Overall Dimension (mm) | |||

| Number (pcs) | Diameter (mm) | Height (mm) | Outside Diameter (mm) | Height (mm) | ||||||

| VIC3R1410 | 3 | 140 | 100 | 495 | 100 | < 8 | 0.613-0.044 | 0.15-1.2 | 14.1 | 3340×2200×3200 |

| VIC3R2115 | 3 | 210 | 150 | 726 | 150 | < 15 | 0.613-0.044 | 0.28-1.8 | 28.2 | 4480×3100×3970 |

| VIC3R2615 | 3 | 260 | 150 | 865 | 150 | < 15 | 0.613-0.044 | 0.35-2.8 | 35.7 | 5000×4100×4850 |

| VIC3R2715 | 3 | 270 | 150 | 884 | 150 | < 15 | 0.613-0.044 | 0.40-3.4 | 42.7 | 5050×4150×4900 |

| VIC4R3016 | 4 | 300 | 160 | 990 | 160 | < 20 | 0.613-0.044 | 0.6-4.5 | 55 | 5250×5000×5500 |

| VIC4R3216 | 4 | 320 | 160 | 1073 | 160 | < 25 | 0.613-0.044 | 1.0-5.2 | 72.5 | 7700×7200×8800 |

Send us a message

If you need our products please write down any questions, we will reply as soon as possible.