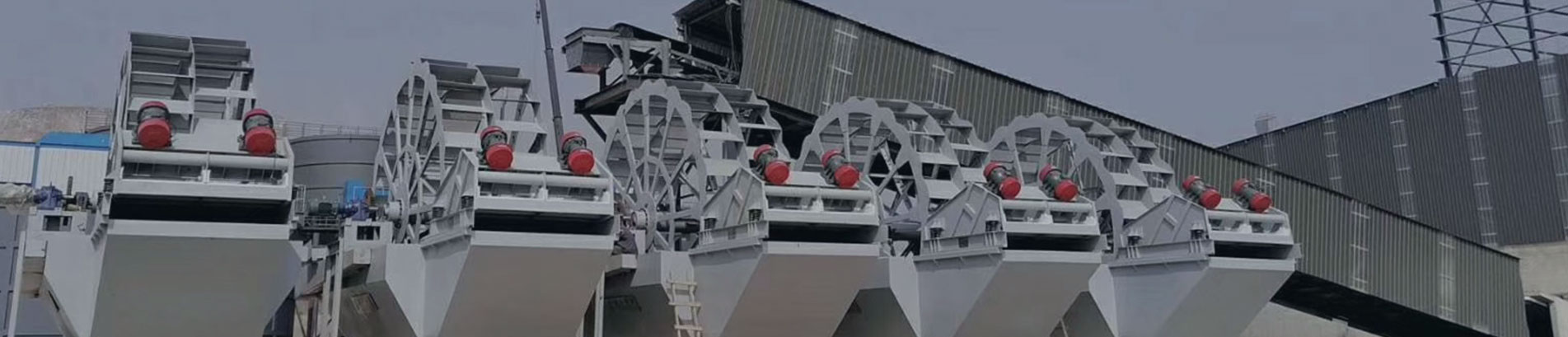

Drum Screen Washing Machine

- Introduction

- Drum screen washing machine, also known as drum screen washing machine and rotary screen washing machine, is a new type of multipurpose water washing equipment with strong mixing function, cleaning function and screening function.

- Capacity

- 30-250t/h

Description

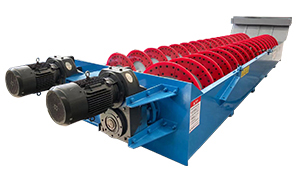

- Drum screen washing machine, also known as drum screen washing machine and rotary screen washing machine, is a new multi-purpose water washing equipment with strong mixing function, cleaning function and screening function. The roller screen washing machine mainly deals with the raw materials with mud content more than 20%. It is a multi-functional equipment that can not only clean the raw materials initially, but also screen the raw materials according to the size of particles.

Advantages

-

1

Wide adaptability of materials: rotary screen is widely used for screening of all kinds of materials. No matter it is inferior coal, slime, soot and other materials, they are screened smoothly. -

2

Simple and diverse feeding modes: the feeding port of rotary screen developed by our company can be designed according to the actual situation on site. No matter it is belt, funnel or other feeding modes, it can be smoothly fed without taking special measures. -

3

High screening efficiency: the equipment can be equipped with a comb type cleaning mechanism. In the screening process, no matter how dirty and miscellaneous the materials entering the screening cylinder can be screened, thus improving the screening efficiency of the equipment.

Structure

The main structure of drum screen washing machine is the screening cylinder, which is composed of several circular screens. The screen is inclined to the ground plane as a whole, and the outside is sealed by a sealed isolation cover to prevent environmental pollution. The screening cylinder rotates at a certain speed through the variable speed deceleration system, the materials are separated from top to bottom through the screening cylinder, the fine materials are discharged from the lower part of the front end of the screening cylinder, and the coarse materials are discharged from the lower end of the screening cylinder. The cylinder rotary screen can be equipped with a comb type cleaning mechanism. In the screening process, the relative movement of the comb type cleaning mechanism and the screening cylinder can achieve the effect of continuous cleaning of the screen body.

Technical Parameters

| Model | Feed Size (mm) | Drum length (mm) | Sieve length (mm) | Sieve size (mm) | Power (KW) | Speed (r/min) | Capacity (t/h) |

| Φ1.5×6m | 250 | 4000 | 2000 | 5-20 | 11 | 12.5 | 30-60 |

| Φ1.8×9m | 300 | 6000 | 3000 | 5-20 | 15 | 10.3 | 50-100 |

| Φ2.0×11m | 350 | 8000 | 3000 | 5-20 | 18.5 | 9.2 | 80-150 |

| Φ2.2×13m | 400 | 10000 | 3000 | 5-20 | 30 | 8.5 | 100-200 |

| Φ2.5×15m | 400 | 10000 | 5000 | 5-20 | 37 | 7.8 | 150-250 |

Send us a message

If you need our products please write down any questions, we will reply as soon as possible.