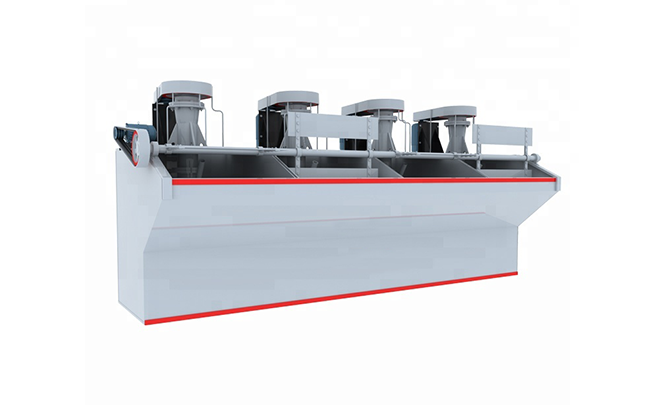

SF Flotation Cell

- Capacity

- 0.02-20 m3/min

- Improvement

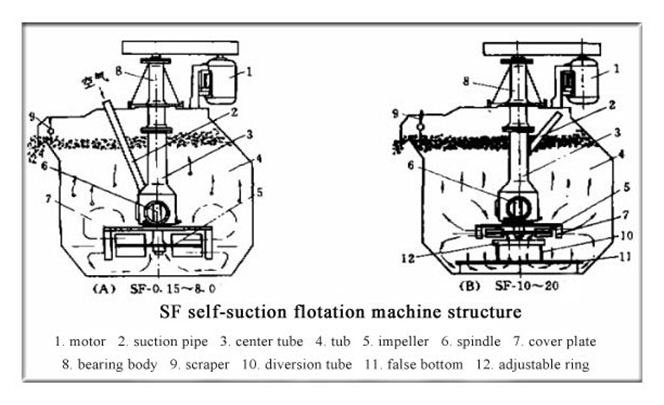

- Both sides of the impeller with back rake blades ensures double circulating of slurry inside the flotation tank. Forward-inclined tank, small dead angle, fast froth movement.

Description

- Introduction

- SF flotation cell is a mechanical agitation type flotation machine with slurry suction and air suction.

Advantages

-

1

Large amount of air suction and low energy consumption; -

2

The reasonable slurry circulation minimizes coarse sand sediments, and is conducive to flotation of coarse particle; -

3

Auto-control device of slurry volume, convenient adjustment; -

4

The impeller with back-style two-side vanes ensures double circulation of slurry in tank; -

5

Low circular velocity of impeller ensures long service life of wear parts; -

6

Mechanical stirring, self-air suction, self-slurry suction; -

7

Combined with the JJF flotation cell to be a set of flotation cell as suction tanks of each operation.

Structure

When the flotation machine is working, as the impeller rotates, the slurry in the tank is sucked from the periphery of the tank from the bottom of the tank to the impeller blade through the bottom of the impeller, and at the same time, the low-pressure air fed by the blower passes through the air distributor of the hollow shaft and the impeller. Enter it. After the slurry and air are thoroughly mixed between the blades, they are pushed upward from the periphery of the upper half of the impeller, and the stator is stabilized and oriented to enter the entire trough. The bubble rises to the foam stabilization zone, and after the enrichment process, the foam overflows from the overflow weir and enters the foam tank. A part of the slurry flows to the lower part of the impeller, and then is stirred by the impeller to remix to form mineralized bubbles, and the remaining slurry flows down to a trough until it becomes a tailing.

Technical Parameters

| Model | Volume | Cell size | Impeller Dia. | Impeller speed | Capacity | Power | Singe cell weight |

| m3 | mm | mm | r/min | m3/min | kw | kg | |

| SF-0.37 | 0.37 | 700×700×750 | 296 | 386 | 0.02-0.4 | 1.5/0.55 | 468 |

| SF-0.7 | 0.7 | 820×900×950 | 350 | 400 | 0.3-0.9 | 3/1.1 | 805 |

| SF-1.2 | 1.2 | 1100×1100×1100 | 450 | 312 | 0.6-1.2 | 5.5/1.1 | 1373 |

| SF-2.8 | 2.8 | 1700×1600×1150 | 550 | 268 | 1.5-3.5 | 11/1.5 | 2138 |

| SF-4 | 4 | 1850×2050×1200 | 650 | 220 | 2--4 | 15/1.5 | 2582 |

| SF-8 | 8 | 2200×2900×1400 | 760 | 191 | 4--8 | 30/1.5 | 4129 |

| SF-10 | 10 | 2200×2900×1700 | 760 | 191 | 5--10 | 30/1.5 | 4486 |

| SF-16 | 16 | 2850×3800×1700 | 760 | 191 | 5--16 | 30×2/1.5 | 8320 |

| SF-20 | 20 | 2850×3800×2000 | 760 | 191 | 5--20 | 30×2/1.5 | 9828 |

| VICJK-3A | 0.35 | 700×700×700 | 300 | 483 | 0.18-0.4 | 2.2/0.55 | 430 |

| VICJK-4A | 0.62 | 820×900×850 | 350 | 400 | 0.3-0.9 | 3/1.1 | 755 |

| VICJK-5A | 1.1 | 1100×1100×1000 | 500 | 330 | 0.6-1.6 | 5.5/1.1 | 1416 |

| VICJK-6A | 2.8 | 1750×1600×1100 | 600 | 280 | 1.5-3.5 | 11/1.1 | 2113 |

| VICJK7A | 5.8 | 2200×2200×1200 | 750 | 240 | 3--7 | 22/1.5 | 3400 |

Send us a message

If you need our products please write down any questions, we will reply as soon as possible.