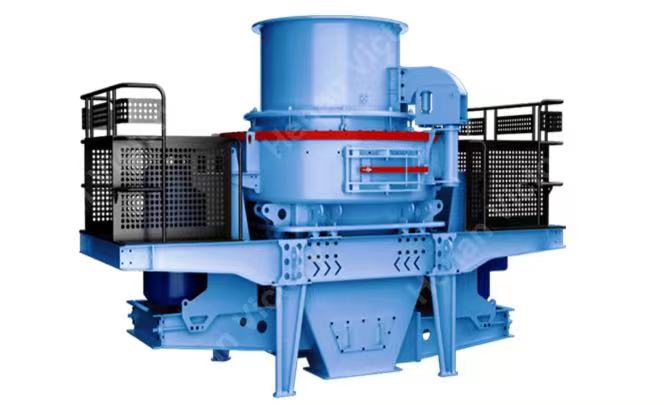

Sand Making Machine

- Capacity

- 60-640t/h

- Improvement

- VSI Sand making machine is the latest product of authoritative experts from both home and abroad,connecting with quarry,mining present working conditions.

Description

- On the basis of introducing German technologies on sand-making machines, we develops and researches a new generation of sand-making machine--- VSI Sand Making machine. It has multiple independent property rights and integrates 3 kinds of crushing modes. Now, VSI Sand Making machine is the core equipment in machine-made sand industry.

Advantages

-

1

The structure is simple, and the operating cost is low. -

2

High efficiency. and low consumption. -

3

It can fine crush, crude grind material and it is easy to maintain. -

4

It is more suitable for crushing mid-hardness materials and high-hardness materials. -

5

Its product is cubic. and the density of piling up is high and the iron pollution is low.

Working

1. Central feeding: Raw materials fall down into the feeding hopper of the VSI sand making machine, then enters the impeller through central entrance inlet, thus the material being accelerated by the high-speed impeller and being thrown out at the speed of 60- 75m/s. It is crushed when hitting the impact plate, and the end products comes out from the discharging outlet.

High Performance VSI Crusher for Sand Making Plant 5% Discount

2. Ring feeding: Raw materials fall down into the feeding hopper, and the materials are divided into two parts by a special plate. Some materials enter the sand making machine's impeller through the center of the plate and the other part of materials falls from Outside of the plate. The materials thrown out earlier crush the materials down from outside, thus the materials crushed and re-crushed.

Technical Parameters

| Model | VSI-7611 | VSI-8518 | VSI-9526 | VSI-1140 | VSI-1145 | VSI-1150 | VSI-1263 | |

| Capacity (t/h) | Center and Sides Feeding | 120-180 | 200-260 | 300-380 | 400-450 | 450-520 | 500-600 | 550-640 |

| Center Feeding | 60-90 | 100-130 | 150-190 | 225-260 | 250-360 | 350-400 | 450-500 | |

| Feeding Size (mm) | Soft Material | <30 | <35 | <40 | <40 | <40 | <50 | <50 |

| Hard Material | <25 | <30 | <35 | <35 | <35 | <40 | <40 | |

| Rotation Speed (r/min) | 1700-1890 | 1520-1690 | 1360-1510 | 1180-1310 | 1100-1310 | 1000-1300 | 900-1000 | |

| Power of the Double Motors (kw) | 110-150 | 180-220 | 264-320 | 400-440 | 400-440 | 250-300 | 300-350 | |

| Hydraulic Lubrication Station | Power of Double Oil Pump | 2×0.31kw | ||||||

| Security & Protection | Double oil pumps complement each other to ensure oil supply; no oil flow, no hydraulic oil will be shutdown automaticly ; water cooling; motor heating starts in winter | |||||||

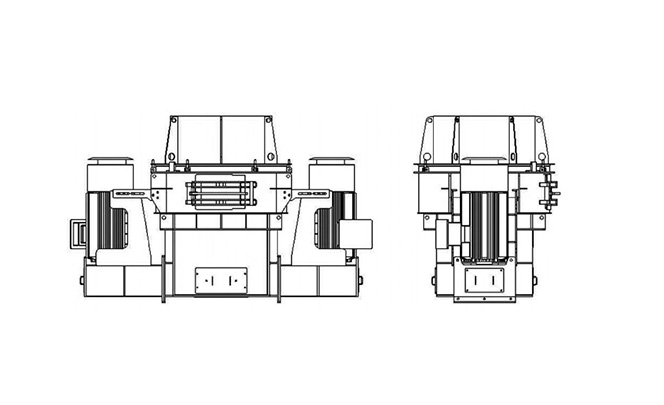

| Overall dimension L*W*H (mm) | 820×520×1270(mm) | |||||||

| Power of Oil Tank Heater | 2KW | |||||||

Send us a message

If you need our products please write down any questions, we will reply as soon as possible.