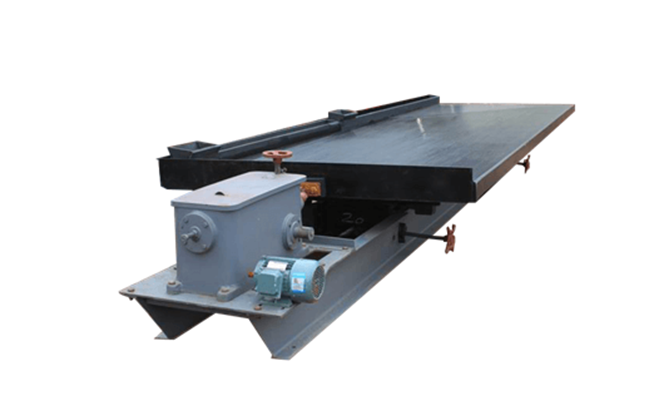

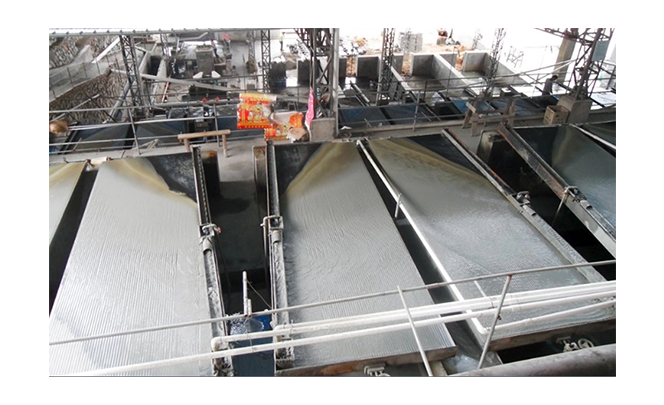

Shaking Table

- Capacity

- 0.05-2.5t/h

- Feeding Size

- 0.15-2mm

- Application Fields

- cement, silicate products, new building materials, refractory materials, fertilizers, black and non-ferrous metal mining, and glass ceramics

Description

- Shaking table which is also called table concentrator, its a gravity separation device for fine minerals . Shaking table is effective in processing precious and base metal, rare metal and non-metallic minerals, widely used in separation of Gold, Silver, Tin, Columbium, Tantalum, Titanium, Barium, Tungsten, Iron, Chrome, Manganese, Zircon, Lead, Zinc, Mercury, Copper, Aluminum etc. Our shaking table can produce mob type, the coarse ore deck is designed for recovering particles size from 0.5 mm to 2 mm; the fine sand deck is designed for recovering fine particles in the range of 0.074 mm to 0.5 mm; the slime deck is designed for recovering super extremely fine particles in the range of 0.037 mm to 0.074 mm.

Advantages

-

1

High recovery ratio; -

2

High concentration ratio; -

3

Simple operation; -

4

Easy installation; -

5

Deck constructed of fiber glass; -

6

Seven different decks to choose; -

7

Long working life; -

8

Adjustable stroke length and speed.

Working Principle

A shaking table is manly composed of eight components, which are table head, electric motor, slope control, deck, feed box, water tank, rifle spokes and lubrication system. The vertical and reciprocating motion of the deck is driven by the crank-connecting actuator. The motor drives the eccentric shafts to rotate and the connecting rod to move up and down. When the connecting rod makes a downward movement, the toggle plate pushes back shaft and reciprocating lever backward. meanwhile, through the tension of spring, it drives the deck to move backward, because the deck is connected with the reciprocating lever by linkage seat. When the rod moves upward, through the force from spring tension, the deck makes a forward movement. The motor drives the eccentric shafts to rotate and the connecting rod to move up and down. With the rod moving down, minerals on tilting deck installed by rifle spokes go into the feed box. meantime, water stored in the water tank impacts the minerals laterally. So by the means of shaking and washing, minerals of different sizes and densities flow from discharge outlets, which separate concentrates and tailings clearly and efficiently. Since the mining table concentrators have been upgrading in line with advanced technologies, their production and accuracy have improved significantly.

Technical Parameters

| Model | Storke(mm) | Feed Size(mm) | Feed density | Capacity(t/h) | Power (kw) | Weight(kg) |

| 6S-4550×2355×1546 | 8-22 | 2-0.074 | 15-30 | 0.6-2.5 | 1.1 | 800 |

| LY-3000×1620×1360 | 6-30 | 2-0.074 | 10-30 | 0.4-1.5 | 1.1 | 550 |

| LY-2100×1050×850 | 12-28 | 2-0.074 | 10-30 | 0.3-0.8 | 1.1 | 350 |

| LY-1100×500×430 | 9-17 | 2-0.074 | 10-30 | 0.05-0.2 | 0.55 | 150 |

Send us a message

If you need our products please write down any questions, we will reply as soon as possible.