Silica Sand Processing Plant

Silica Sand is one of the most common minerals in the earth's crust. The main components of quartzite, vein quartz, and quartz sand are all quartz. Before industrial application,Silica Sand generally needs to undergo certain processing, and the specific processing techniques include: crushing and classification, beneficiation and purification, surface modification and other processes. Among them, flotation is an important process in beneficiation and purification.

Application

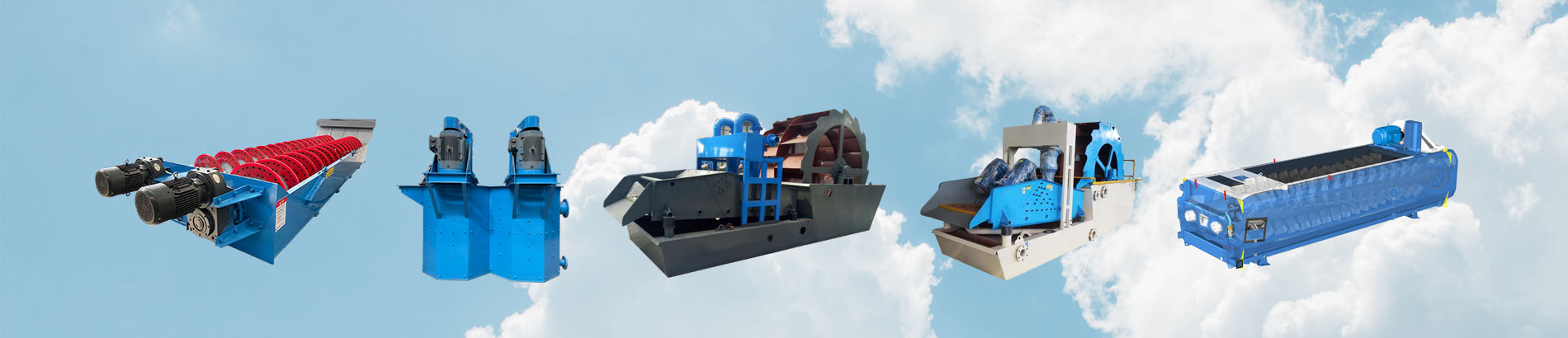

Silica Sand is an important industrial mineral raw material, widely used in glass, casting, ceramic metallurgy, construction, chemical, plastic, rubber and other industries. The composition of quartz sand is relatively complex, and besides iron minerals, there are often mica, feldspar and clay minerals. Our quartz sand beneficiation process can be applied to quartz sand containing iron or mica.Silica sand beneficiation generally requires scrubbing, desliming, or the use of shakers, magnetic separation, etc. to remove iron-containing minerals, and then flotation. Before flotation, vigorously stir in a thick ore slurry to wipe off the oxidation of the quartz surface The iron film is then floated with fatty acid collectors to remove iron-containing minerals, and the product in the tank is quartz concentrate.The specific process is as follows:

Scrubbing and desliming

Scrubbing refers to the removal of thin-film iron, adhesive and muddy impurity minerals on the surface of the quartz sand by mechanical force and the grinding and peeling force between the sand grains, and further smashing of unconsolidated mineral aggregates, and then further purification of the quartz sand by classification operations Effect. There are mainly rod scrubbing and mechanical scrubbing. The main factors affecting the scrubbing effect are the structural characteristics and configuration of the scrubbing machine; the secondary factors are scrubbing time and scrubbing concentration (the scrubbing concentration is generally 50%-60%). There are mainly mechanical scrubbing, rod scrubbing, high-efficiency strong scrubbing with medicines, and ultrasonic scrubbing.

Magnetic separation

Magnetic separation is mainly used to remove magnetic minerals in quartz sand. For example, weak magnetic minerals such as hematite, limonite, and biotite can be removed by a strong magnetic machine, while strong magnetic minerals such as magnetite can be removed by a weak magnetic separator Remove.

Flotation

Flotation is used to remove some impurities that cannot be removed by magnetic separation, such as feldspar and mica in the quartz sand, to further improve its purity.

Acid leaching

Acid leaching utilizes the characteristic that quartz is insoluble in acid (except HF acid), and other impurity minerals can be dissolved by acid, which can realize further purification of quartz. In recent years, a new microbial leaching method has appeared, which refers to the use of microorganisms to leaching thin film iron or immersion iron on the surface of quartz sand particles.

If you need our products please write down any questions, we will reply as soon as possible.