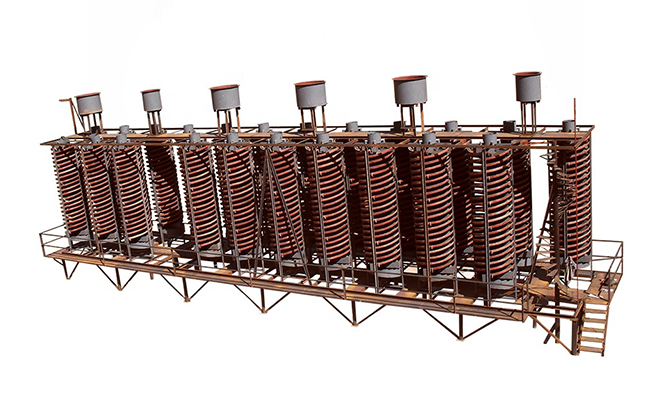

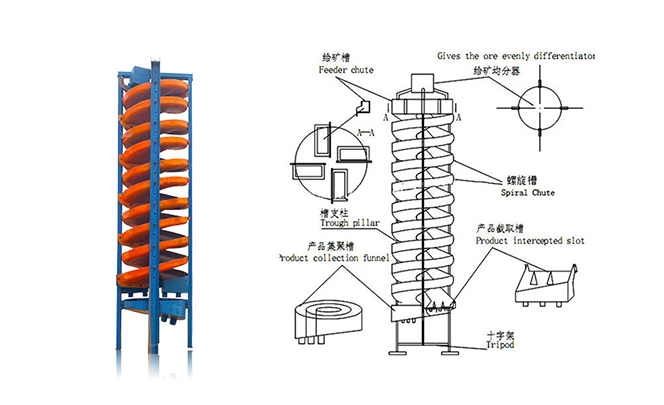

Spiral Chute

- Capacity

- 0.15~16t/h

- Improvement

- There are 3 kinds of chute for user to choose, glass steel chute, wear-resistant rubber liner, polyurethane rubber liner with brand Victory

Description

- Introduction

- A gravity separation equipment of separating minerals with different weight by the inertial centrifugal force generated in the spiral motion of pulp. This equipment is suitable for separating non-ferrous metals, rare metals and non-metal ores whose granularity is 0.3--0.02 mm such as iron ore, ilmenite, chromite, pyrite, zircon, rutile, monazite, tungsten, tin, tantalum and niobium ore. It is the ideal equipment for mining and for ore beneficiation, especially for the mining of sand ore in the coast, Riverside, beach, and brook.

Advantages

-

1

High efficiency, high recovery and accurate ore separarion, no need of power; -

2

Light weight, rust, wear and corrosion ressistance; -

3

Low operation cost and long service life; -

4

Strong adapability to the variation of feeding quantity, density, particle size and grade.

Structure

The uniform ore slurry is slowly fed to the spiral groove surface through the ore feeding trough installed at the head end of the spiral trough for sorting. The end of the spiral groove is equipped with a valve block-type product intercepting groove, and the sorted products are divided into three types according to the grade along the radial direction. The position of the regulating valve block is used to change the intercepting width of each product, and the product gathering bucket collects and derives the intercepted multi-head ore streams. The cross section and the slope change of the curve are especially suitable for the selection of fine particle materials.

Spiral chute is suitable for treatment of the 0.6-0.03mm lode and placer, but high mud content is bad for separation. At present, the spiral chute has been widely used in the treatment of iron ore, tungsten, tin ore, niobium tantalum ore, coastal and riverside placer and gold ore.

Technical Parameters

| Model | VLL-2000 | VLL-1500 | VLL-1200 | VLL-900 | VLL-600 | VLL-400 | |

| Outside Diameter (mm) | 2000 | 1500 | 1200 | 900 | 600 | 400 | |

| Screw Pitch (mm) | 1200 | 900, 675 | 900, 720, 540 | 675, 540, 405 | 450, 360, 270 | 240, 180 | |

| Pitch Diameter Ratio | 0.6 | 0.48, 0.36 | 0.75, 0.6, 0.45 | 0.75, 0.6, 0.45 | 0.75, 0.6, 0.45 | 0.6, 0.45 | |

| Lateral Dip Angle (degree) | 9° | 9° | 9° | 9° | 9° | 9° | |

| Max. Screw Numbers Per Set | 3 | 4 | 4 | 4 | 2 | 2 | |

| Feed Size (mm) | 2.00~0.04 | 0.8 ~0.037 | 0.3~0.03 | 0.3 ~0.03 | 0.2~0.02 | 0.2 ~0.02 | |

| Feed Density (%) | 30 ~55 | 30 ~55 | 25 ~55 | 25 ~55 | 25 ~55 | 25 ~55 | |

| Capacity (t/h) | 7~10 | 6~8 | 4~6 | 2~3 | 0.8~1.2 | 0.15~0.2 | |

| Overall Dimension | Length (mm) | 2120 | 1600 | 1360 | 1060 | 700 | 460 |

| Width (mm) | 2120 | 1600 | 1360 | 1060 | 700 | 460 | |

| Height (mm) | 5600 | 5300 | 5230 | 4000 | 2600 | 1500 | |

| Weight (kg) | 900 | 850/800 | 700/650/600 | 450/400/350 | 120/100/80 | 50 | |

Send us a message

If you need our products please write down any questions, we will reply as soon as possible.