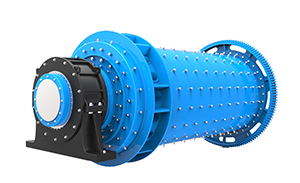

Three-ring Micro Powder Mill

- Capacity

- 0.35-6.5t/h

- Processed Materials

- Limestone, calcite, dolomite, petroleum coal, gypsum, barite, marble, talc, coal powder, etc.

Description

- Introduction

- The machine is designed to produce super-fine powder or micro powder of different materials with hardness less than 6 in Moh's scale and humidity less than 6 percent such as kaolin, limestone, calcite, marble, talcum, barite, gypsum, dolomite, bentonite mud, mica, pyrophyllite, sepiolite, diatomite, graphite, alunite, fluorite, potassium feldspar, phosphorite, pigment and so on. The granularity of the end products is 325-2500 meshes (0.044-0.005mm).

Advantages

-

1

Exquisite appearance; -

2

The whole bevel gear transmission; -

3

Internal thin oil lubrication system; -

4

Curved duct; -

5

Curved surface shovel with exchangeable blade; -

6

Isolated cyclone collector; -

7

No resistance inlet volute (small observation door without vortex).

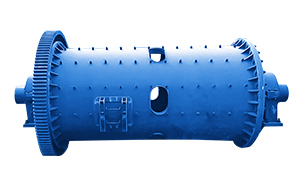

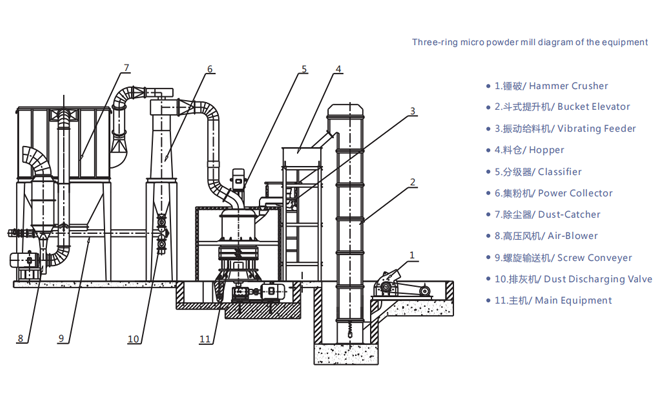

Structure

The motor of main equipment drives the main shaft and dial through reducer, and the dial drives numbers of rollers moving in the ring channels via pins. After being crushed by hammer crusher, big materials become small ones and they are sent to the hopper by elevator. The electromagnetic vibrating feeder sends them to the middle of first layer of dial evenly; the materials will be driven to the edge of dial by centrifugal force and fall into the ring channels and are pressed, crushed and ground by the grinding rings and rollers. After ground in the first layer of the dial, the materials fall into the second and third layer and are crushed and ground. The high-pressure centrifugal blower inhales air from outside and blow the materials from the third layer to powder classifier. The rotating turbo in the powder classifier makes the coarse materials return to the mill and reground, while the fine powder mixed in the air goes into the cyclone collector and is discharged from the bottom via discharge valve. The air with very little fine powder is purified by pulse dust catcher and discharged by blower and muffler.

Technical Parameters

| Model | Roller Numbers (pcs) | Ring Diameter (mm) | Ring Numbers (pcs) | Max.Feeding Size(mm) | Output Size (mm) | Capacity (kg/h) | Motor Power(Kw) | Overall Dimension (mm) |

| HGM80 | 21 | ø800 | 3 | 20 | 0.044-0.005 | 600-4500 | 55 | 13000×3000×5800 |

| HGM90 | 24 | Ø900 | 3 | 20 | 0.044-0.005 | 700-5500 | 37×2 | 14700×4800×7200 |

| HGM100 | 27 | Ø1000 | 3 | 20 | 0.044-0.005 | 900-6500 | 110 | 18000×4000×8600 |

| HGM110 | 36 | Ø1000 | 3 | 20 | 0.044-0.005 | 1000-7500 | 110 | 18000×4600×8600 |

Send us a message

If you need our products please write down any questions, we will reply as soon as possible.