Description

- Introduction

- The TGM series superfine grinding mill is the new-type product with high-level techniques, developed by HENAN VICTORY MACHINERY, with more than 20 year’ experience in the R&D of powder grinding equipment, absorbing the good powder grinding techniques and concepts. It is applied to process the non-flammable and explosive materials with a Mohs hardness of less than 9.3 and a humidity of less than 7%, such as quartz, feldspar, calcite, limestone, talc, etc. The final product’s fineness can be adjusted at random between 0.18mm (80 mesh)-0.01mm (800 mesh). TGM series superfine grinding mill is one new type product with the international advanced technological level developed by our company by absorbing the domestic and overseas excellent technology and concept on the basis of the actual situation of customers and the experience of our researchers in the past 40 years.

Advantages

-

1

Exquisite appearance; -

2

The whole bevel gear transmission; -

3

Internal thin oil lubrication system; -

4

Curved duct; -

5

Curved surface shovel with exchangeable blade; -

6

Isolated cyclone collector; -

7

No resistance inlet volute (small observation door without vortex).

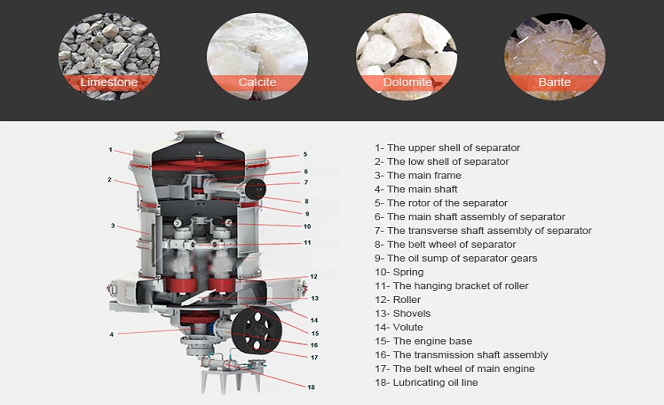

Structure

Large materials are crushed by Jaw crusher to the needed sizes firstly, then the materials are elevated to storage hopper by bucket elevator, third, the materials are fed into the grinding chamber for grinding by vibrating feeder equably and continuously. The powder after grinding goes upwards together with the airflow, after separating by powder separator, those which can meet the fineness requirement enters into the cyclone powder collector through pipe together with the airflow, and then discharged from the discharge valve as final products. The airflow is sucked into centrifugal blower through wind recycling pipe at the upper part of cyclone powder collector. The mainframe is driven by the speed reducer through the central axis in the mill. The quincunx stand connected with the upper part of central axis, at the quincunx stand, rollers are set and by which the vibrating pivot formed. Below the quincunx stand and rollers there is shovel system. Materials are fed into the space between rollers and shovels when they are turning, and then be grinded by the pressure produced when rollers are turning, thus powder is made.

Technical Parameters

| Item//Model | TGM100 | TGM130 | TGM160 |

| Roller piece | 4 | 5 | 6 |

| Roller Diameter×Height(mm) | 320×200 | 410×240 | 440×270 |

| Ring Inner Diameter×Height(mm) | 980×200 | 1280×240 | 1600×270 |

| Speed Of Main frame (r/min) | 130 | 103 | 82 |

| Max. Input Size (mm) | <25 | <30 | <35 |

| Product Size (mm) | 1.6~0.045 | 1.6~0.045 | 1.6~0.045 |

| fineness can reach to 0.038 | fineness can reach to 0.038 | fineness can reach to 0.038 | |

| Capacity (t/h) | 3~8 | 6~15 | 9~22 |

| Overall Dimension (mm) | 7910×5365×8310 | 8910×7000×9645 | 12550×5700×8355 |

| Weight (t) | 16 | 26.1 | 35 |

Send us a message

If you need our products please write down any questions, we will reply as soon as possible.