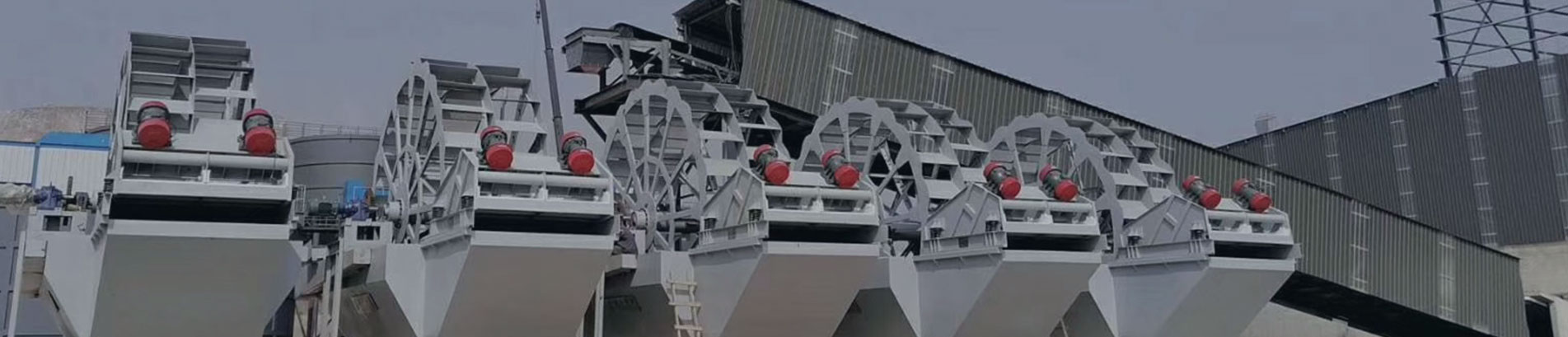

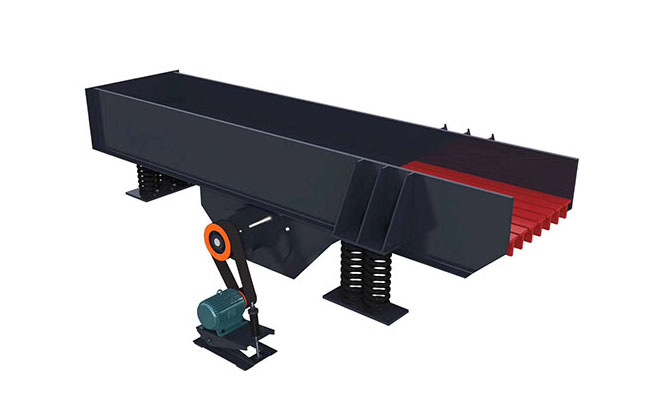

Vibrating Feeder

- Capacity

- 80-1000t/h

- Improvement

- The crushing machine can feed continuously and evenly with coarse screening in the gravel production line.

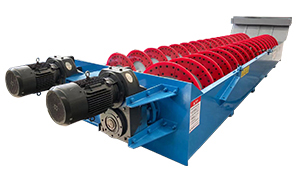

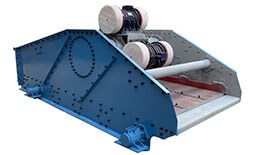

Description

- The ZSW series vibrating feeder adopts the vibrating motor to produce vibration force.During processing the equipment can send various materials into the crushers in the given time,separating the raw materials primarily.It is widely used in metallurgy,coal ore,construction materials,etc.

Advantages

-

1

Smooth vibration and reliable operation. -

2

Special grid design can prevent material blockage and adjustable grid gap. -

3

There are more wear parts to prevent the wear parts from being worn by small materials,and the small materials are separated to increase the output. -

4

Optional variable frequency speed control motor,adjust the frequency to change the output,easy to control the feeding amount,no need to start the motor frequently.

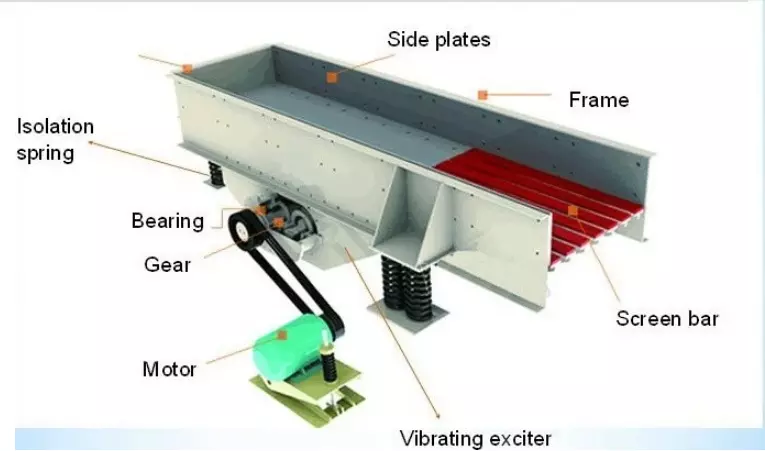

Working

The vibrating feeder is mainly composed of a vibrating frame, a spring ,a vibrator, a motor vibrating frame and a motor. The exciter is composed of two eccentric shafts of a specific position and meshed by gears. When assembling, the two gears must be meshed by the mark, and driven by the motor to rotate the two eccentric shafts, thereby generating a huge synthetic linear exciting force. The body is forced to vibrate on the support spring, and the material is powered by the vibration, and the sliding and throwing motion is performed on the through, so that the material is moved forward to achieve the feeding purpose. When the material passes through the sieve strip on the tank body, the smaller material can fall through the gap of the screen strip, and the screening effect can be achieved without going through the crushing process of the next lane.

Technical Parameters

| Model | Feed partical size (mm) | Processing capacity (t/h) | Motor Power (kw) | Installation angle (°) | Total weight (kg) | Slot Size (mm) | Dimensions (mm) |

| GZD-650×2300 | 300 | 80 | 1.1*2 | 10 | 2798 | 650*2300 | 2300*1360*780 |

| GZD-750×2500 | 350 | 100 | 1.1*2 | 10 | 3260 | 750*2500 | 2500*1460*780 |

| GZD-850×3000 | 400 | 120 | 3*2 | 10 | 3607 | 850*3000 | 3110*1800*1600 |

| GZD-1000×4200 | 500 | 150 | 5.5*2 | 10 | 3895 | 1000*3600 | 3850*1950*1630 |

| GZD-1100×4200 | 580 | 240 | 5.5*2 | 10 | 4170 | 1100*4200 | 4400*2050*1660 |

| GZD-1300×4900 | 650 | 450 | 7.5*2 | 10 | 5200 | 1300*4900 | 5200*2350*1750 |

| GZD-1500×5600 | 1050 | 450-800 | 11*2 | 10 | 7500 | 1500*5600 | 5700*2000*1750 |

| ZSW-380×95 | 500 | 100-160 | 11 | 0 | 4823 | 3800*960 | 3820*1640*1320 |

| ZSW-490×110 | 630 | 150-320 | 15 | 0 | 6647 | 4900*1100 | 4980*1830*1320 |

| ZSW-490×130 | 750 | 400-600 | 22 | 0 | 8760 | 4900*1300 | 4980*2580*2083 |

| ZSW-600×130 | 750 | 400-600 | 22 | 0 | 9250 | 6000*1300 | 6082*2580*2083 |

| ZSW-600×150 | 800 | 500-700 | 30 | 0 | 10130 | 6000*1500 | 6086*2662*1912 |

| ZSW-600×180 | 800 | 700-1000 | 37 | 0 | 13750 | 6000*1800 | 6310*3262*2230 |

Send us a message

If you need our products please write down any questions, we will reply as soon as possible.