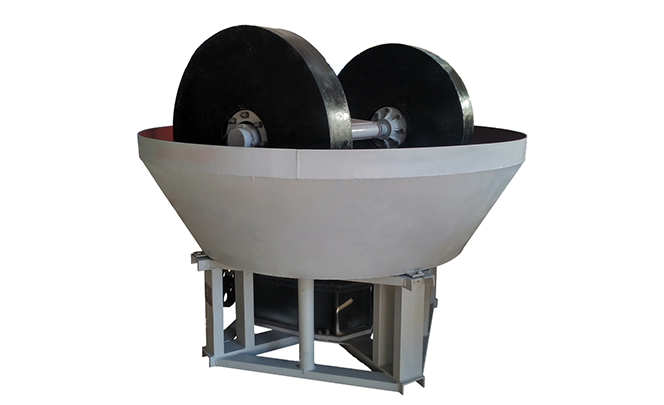

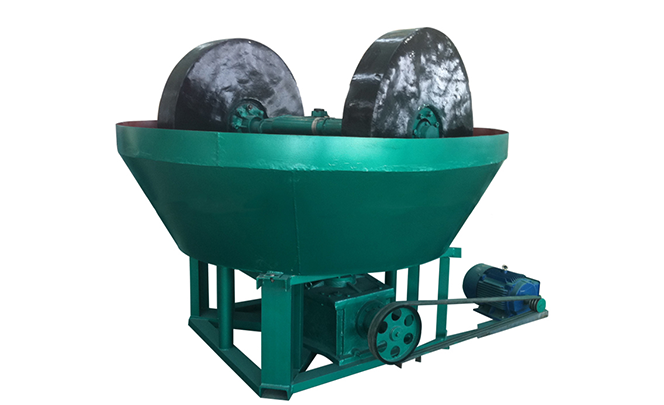

Wet Pan Mill

- Capacity

- 0.3-4 t/h

- Available models

- 850;900;1000;1100;1200;1300;1350;1400;1500;1600

Description

- Wet grinding machine also called wet gold grinding machine is used for amalgamation gold extraction of sulfide-free gold mines and is suitable for operations in field areas without power supply by equipped with a diesel generator. This machine, which has functions of crusher and ball mill, can crush the ores once for all in the purpose of gold extraction in amalgamation method. Based on the different structure it is divided into double roller grinding and three roller grinding. Wet pan mill mainly used for grinding operation, such as all kinds of ferrous metal, non-ferrous metal, non-metallic minerals, and the separation of gold, silver, lead, iron, copper-gold and so on. Wet Pan Mill for gold selection, which is the excellent equipment for replacing ball mill, is the first choice of milling equipment for small and medium-sized gold mining plant. Wet pan is a new-type mill, with a small investment, high production advantages. The wet pan grinding mill is named by the diameter of the roller. Φ1300, Φ 1350, Φ 1400, Φ 1500, Φ 1600 is suitable for selection of iron ore, molybdenum ore, lead ore, zinc ore, antimony ore and so on. Φ 850, Φ 900, Φ 1000, Φ 1100, Φ 1200 is suitable for selection of gold ore.

Advantages

-

1

Long life, the use of safe and reliable, easy maintenance, simple structure, easy maintenance and replacement; -

2

Add special wear-resistant materials, strong wear resistance, durable, low noise, high production efficiency; -

3

The machine investment is small, quick, covers an area of small, is ideal equipment for the mining area and small business; -

4

All the ball mill can choose the mine, grinding gold machine can be used.

Working

Wet pan mill for gold selection, which mainly consists of the power plant, body frame, water basin, runner wheel, and grinding base, works under the wheel grinding system.

First reduction box would be driven by the motor , then under the drive of reduction box, the torque is transmitted to the upper cross axle through the large vertical shaft and then to the runner wheels through the straining beams installed on both ends of the cross axle The runner wheels are driven to rotate anti-clockwise along the horizontal direction of the cross axle . When the runner wheels are working, They could not only revolve around the large vertical shaft of the wet pan mill but also revolve their own axles. The groundings of the runners and the bases of the runners and the bases of the runners and the bases of the runners Autorotation, as well as the repeated squeeze, curating and grinding.

Technical Parameters

| Model | Specification | Input size (mm) | Capacity (t/h) | Power(kw) | Weight (t) | Rotate speed(r/min) |

| 1600 | 1600x400x200x500±20 | 30 | 4 | 30 | 14.5 | 20-22 |

| 1500A | 1500x350x200x460±20 | 30 | 3 | 22 | 13.5 | 20-22 |

| 1500B | 1500x350x150x460±20 | 30 | 2.5-3 | 22 | 12.3 | 20-22 |

| 1500C | 1500x300x150x420±20 | 30 | 2-2.5 | 22 | 11.3 | 20-22 |

| 1400 | 1400x250x150x350±20 | 30 | 1.5-2 | 18.5 | 8.5 | 16-18 |

| 1300 | 1300x250x150x350±20 | 30 | 1.5 | 15 | 7.5 | 16-18 |

| 1200A | 1200x200x80x270±20 | 30 | 0.9-1.2 | 11 | 5.5 | 17-19 |

| 1200B | 1200x200x80x250±20 | 30 | 0.8-1.0 | 11 | 5.5 | 21-23 |

| 1100 | 1100x200x80x250±20 | 30 | 0.6-0.8 | 7.5 | 5 | 17-19 |

| 1000 | 1000x200x80x250±20 | 30 | 0.5 | 5.5 | 4.5 | 13-15 |

| 900 | 900x200x80 | 30 | 0.3 | 5.5 | 3 | 10-15 |

Send us a message

If you need our products please write down any questions, we will reply as soon as possible.