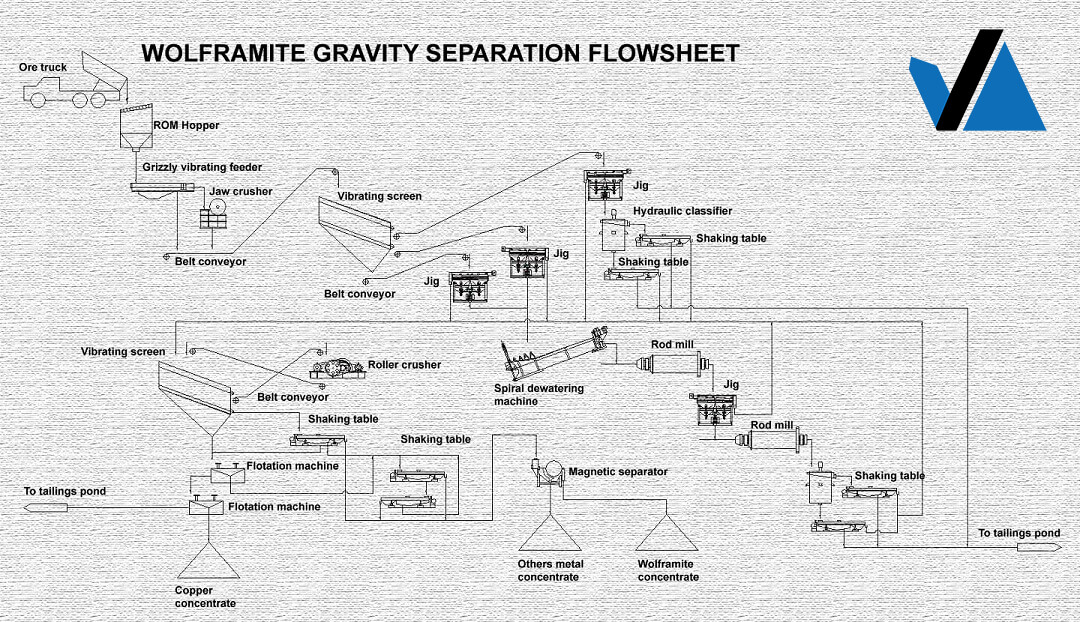

Wolframite Ore Dressing Process

Wolfram ore has the characteristics of high mining dilution rate, low grade, coarse mineral inlay size, high density, low hardness, easy muddy, deep color, etc. The beneficiation method is mainly heavy selection. The process flow of wolframite beneficiation is generally divided into several stages, such as rough selection, gravity separation, beneficiation and fine mud separation. The main processes of roughing include photoelectric beneficiation, heavy-medium beneficiation and pre-selection and waste discarding with moving screen jigging machine; the main processes of gravity separation include multi-stage grinding, multi-stage jigging, multi-stage shaker, centralized fine mud treatment, etc.; Mainly adopts the combined process flow of gravity separation, magnetic separation, flotation, Taiwan flotation and other beneficiation methods; the fine mud separation mainly adopts the method of centralized return and separate treatment.

Application

Tungsten ore gravity dressing technology is especially suitable for wolframite ore with uneven grain size.Wolframite beneficiation process includes four parts: pre-selection, grading and re-selection, selection and comprehensive recovery, and fine mud treatment. Washing, desliming and grading are carried out before the pre-selection. The pre-selection adopts methods such as manual selection, photoelectric separation and heavy medium beneficiation.

In the mining of wolframite, a large amount of wall rock (waste rock) is often mixed in the ore, and it also contains 3%-10% of the primary sludge. Therefore, the pre-selection method should be used to discard most of the surrounding rock when the raw ore is sorted. , Pre-selection discards the waste rock in the original ore, and the pre-selected ore is crushed.

Wolframite beneficiation plants generally use a three-stage crushing process: coarse crushing, medium crushing and fine crushing to crush ore. The coarsely crushed ore shall have a lumpiness of not more than 1m, and then undergo medium and fine crushing, and sieving into ore with a particle size of less than 12mm for classification and gravity separation.

Due to the high density of wolframite minerals, the re-election cost is low. Therefore, when sorting wolframite, first consider re-election. Shaker is used for beneficiation to further improve the grade of tungsten concentrate. The characteristics of the process are: three-stage jigging and multi-stage shaker selection. That is, the coarse and medium-grained jigging tailings are ground with a rod mill and then jigging, and the tailings are returned to the vibrating screen for classification to form a large closed circuit; the fine-grained jigging tailings are classified into a shaker for sorting; Or re-grind and re-select, 1.5-3mm start to throw tailings; the sludge is removed and treated separately.

The black tungsten coarse concentrate obtained by gravity separation contains many other useful minerals and gangues in addition to tungsten-containing minerals. The purpose of selection is to exclude gangues and comprehensively recover other useful minerals. Due to the complexity of beneficiation, special sections or beneficiation plants are usually established.

If you need our products please write down any questions, we will reply as soon as possible.