-

CIL Gold Carbon Leaching Process

The carbon leaching method (CIL) is developed on the basis of the gold extraction process for the replacement of fully viscous zinc cyanide powder. It is mainly suitable for processing low sulfur oxidized minerals with a lot of sludge.

-

CIP Gold Carbon In Pulp Process

Gold extraction by carbon slurry process is mainly composed of cyanide leaching, activated carbon adsorption, desorption, and carbon regeneration.

-

Gold Flotation Production Line

Flotation is widely used in gold ore processing plant to process the rock gold ,commonly used in dealing with highly floatable sulfide minerals containing gold ore.

-

Alluvial Gold Processing Plant

Alluvial gold processing mainly applies to processing alluvial gold contains mainly free gold blended with sand or soil.

-

Chrome Ore Dressing Process

Chromium is an important alloy element for smelting stainless steel, internal heating steel, alloy tool steel, alloy structural steel and various types of cast iron. The chromite ore usually used to produce ferrochromium contains more than 38% chromium.

-

Tin Ore Dressing Process

Because the density of cassiterite is higher than that of symbiotic minerals, the traditional process of tin ore beneficiation is gravity beneficiation. With the passage of time, the particle size of cassiterite in the selected ore continues to become finer, and the cassiterite flotation process appears.

-

Nickel Ore Dressing Process

Nickel ore is mainly divided into copper-nickel sulfide ore and nickel oxide ore, and their beneficiation and processing methods are different.

-

Wolframite Ore Dressing Process

Wolfram ore has the characteristics of high mining dilution rate, low grade, coarse mineral inlay size, high density, low hardness, easy muddy, deep color, etc. The beneficiation method is mainly heavy selection.

-

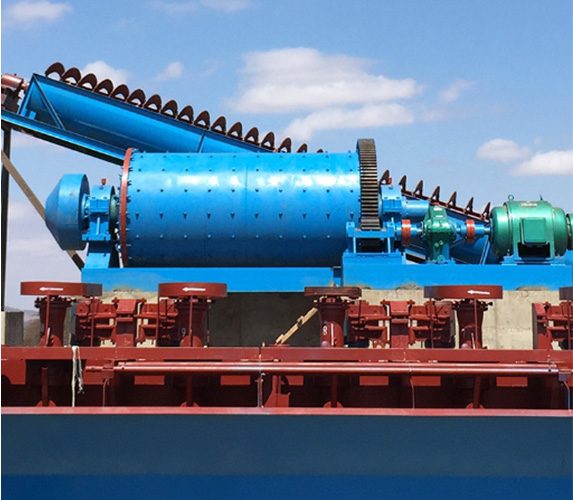

Magnetite Ore Dressing Process

The magnetite beneficiation production line is common in the beneficiation process, and it is also the more commonly used one. It has the advantages of simple and easy operation, reasonable process, economic investment, economy and environmental protection, and high recovery rate.

-

Hematite Separation Process

Hematite is widely distributed and involves many types of minerals. Therefore, the beneficiation method is not single. Early hematite ore beneficiation generally used gravity separation technology, mainly including jigs, centrifugal concentrators, spiral chutes, spiral concentrators, shaking tables, etc.

-

Lead-Copper-Zinc Polymetallic Ore Dressing Process

According to the high sulfur and complex characteristics of copper-lead-zinc ore, a combined flotation-concentrate regrinding process is generally used. In the lead-zinc ore beneficiation process, the equipment usually selected is copper-lead-zinc mixed flotation machine and high-efficiency stirring tank.

-

Molybdenum Ore Dressing Process

The molybdenum ore dressing process is mainly flotation, and the recovered molybdenum mineral is molybdenite. Sometimes in order to improve the quality of molybdenum concentrate and remove impurities, the molybdenum concentrate is subjected to chemical beneficiation.